High-density tungsten alloy aircraft maintenance tools are tools specially designed for aircraft maintenance and repair tasks, and their manufacturing materials contain high-density tungsten alloy. These tools are designed and manufactured to meet the specific needs of aircraft maintenance missions, including aircraft, helicopters, flying cars and more. The characteristics of high-density tungsten alloy aircraft maintenance tools include high strength, wear resistance, high temperature resistance and corrosion resistance, which make them suitable for performing a variety of maintenance tasks in complex and challenging environments. Here are some common types and applications of high-density tungsten alloy aircraft maintenance tools:

- Drill bits and cutting tools: High-density tungsten alloy drill bits and cutting tools are used in aircraft maintenance to drill, trim and cut metal and other materials for repair and installation work.

- Pliers and wrenches: High-density tungsten alloy pliers and wrenches are used for the removal and installation of bolts and nuts on spacecraft and aircraft for repair and maintenance work.

- Welding and brazing equipment: High-density tungsten alloy welding and brazing equipment is used to perform welding and brazing repairs on spacecraft structures and components to restore their strength and integrity.

- Measuring and testing instruments: High-density tungsten alloy measuring and testing instruments include various measuring tools, instruments and detectors, used to check and measure various parameters and performance of aircraft.

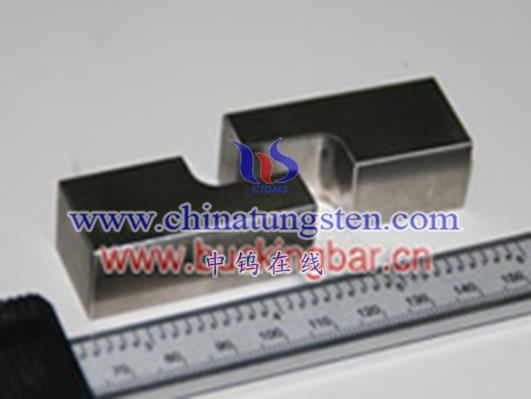

- Jigs and Fixtures: High-density tungsten alloy jigs and fixtures are used in spacecraft repair work to maintain the position and stability of components for repair and assembly.

- Power tools: High-density tungsten alloy power tools include drills, electric saws, grinders, etc., used for various processing and repair work in aircraft maintenance.

- Auxiliary tools: High-density tungsten alloy aircraft maintenance tools also include various auxiliary tools, such as thread repair tools, pneumatic tools, cooling tools, etc., used for special maintenance tasks.

These tools need to be designed and manufactured to meet high standards of precision and quality to ensure they can be used safely and effectively during aircraft maintenance tasks. The use of high-density tungsten alloy provides longer tool life and better performance, especially in high-temperature, high-pressure and high-wear environments. These tools are critical to keeping aircraft operational and performing maintenance tasks, while ensuring flight safety and passenger safety.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595