CTIA GROUP LTD’s high-density tungsten alloy aircraft maintenance rivet set (Tungsten Heavy Alloy Aircraft Maintenance Rivet Set) is a special tool used for aircraft maintenance. It has many unique advantages in the field of aviation maintenance. These advantages cover many aspects such as material properties, manufacturing processes and maintenance efficiency. The advantages of high-density tungsten alloy aircraft maintenance rivet rods manufactured by CTIA GROUP LTD will be introduced in detail below.

- Material characteristics and advantages:

- High density: CTIA GROUP LTD’s high-density tungsten alloy is a very heavy metal and has a higher density than other common materials, such as steel or aluminum. This high density helps to increase the efficiency of pressure transmission of the rivet leaf, rivet or rivet nut, thereby increasing the stability and reliability of the connection. In aircraft maintenance, reliable connections are critical because they withstand the tremendous stress and vibration of the aircraft.

- Wear resistance: CTIA GROUP LTD’s high-density tungsten alloy has excellent wear resistance due to its hardness and corrosion resistance. In aircraft maintenance, tools are often required to handle various metal surfaces, including aluminum, steel, titanium, etc. Using rivet bars made from high-density tungsten alloy reduces wear when working with these metals, extending tool life.

- High-temperature stability: Aircraft maintenance may require working in high-temperature environments, such as during welding or heat treatment. High-density tungsten alloys have excellent high-temperature stability, maintaining their mechanical properties and maintenance tool stability. This helps ensure service tool reliability in high-temperature environments.

- Non-magnetic: High-density tungsten alloy is a non-magnetic material, which means it will not be disturbed by magnetic fields. This is important for aircraft maintenance work, as many components and systems on aircraft are very sensitive to magnetic fields. Using non-magnetic tools can reduce interference with aircraft systems and ensure the accuracy and safety of repair work.

- Density adjustability: The high-density tungsten alloy manufactured by CTIA GROUP LTD can adjust the alloy formula as needed to meet the requirements of different maintenance tasks. This flexibility allows the riveting rod to perform optimally in different situations, ensuring the efficiency and quality of repair work.

- Manufacturing process advantages:

- Machinability: Although high-density tungsten alloy has high hardness, it still has certain machinability. This means that manufacturing processes can be performed relatively easily, including machining processes such as cutting, drilling, milling and grinding. This makes it relatively easy to manufacture high-density tungsten alloy rivet rods that can meet the requirements of specific repair tasks.

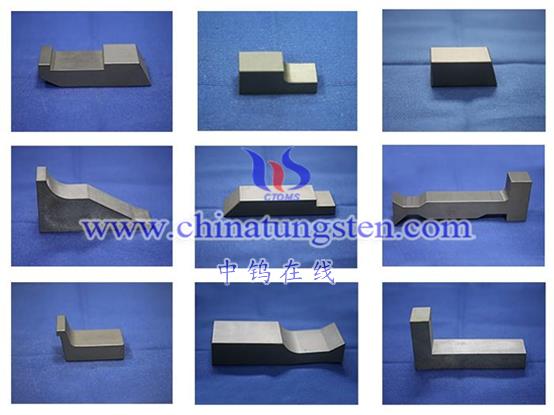

- High-precision manufacturing: Aircraft maintenance tools require high precision to ensure accuracy and reliability during the maintenance process. CTIA GROUP LTD’s high-density tungsten alloy rivet jacking rods can be manufactured through high-precision manufacturing processes to ensure the accuracy of their size and shape to meet the high requirements of maintenance work.

- Customizability: Since the alloy composition of high-density tungsten alloy is adjustable, manufacturers can customize it according to the needs of different maintenance tasks. This means that jacking bars can be produced in a variety of sizes and shapes to suit different types of joints and repair tasks.

- Maintenance efficiency advantages:

- Improve the quality of connectors: High-density tungsten alloy rivet rods can improve the quality and stability of connectors. They provide greater pressure transfer efficiency and reduce joint looseness and vibration, thereby extending the service life of the joints.

- Increase maintenance speed: Due to the high hardness and wear resistance of high-density tungsten alloy riveting rods, maintenance personnel can complete maintenance tasks more quickly. This saves maintenance time, reduces downtime and increases aircraft availability.

- Reduce maintenance costs: By improving maintenance efficiency and connection quality, high-density tungsten alloy riveting rods can reduce maintenance costs. Fewer repairs and longer connection life reduce material and labor costs.

- Enhanced maintenance safety: The high-temperature stability and non-magnetic properties of high-density tungsten alloy rivet rods can enhance the safety of maintenance tools. They are not susceptible to damage from high-temperature environments and do not interfere with aircraft systems, reducing risks during maintenance.

- Versatility: High-density tungsten alloy riveting rods can be used for a variety of different types of connections, including riveting pages, rivets and rivet nuts. This versatility reduces the need for tool inventory, simplifies repair operations, and increases productivity.

Summarize:

The high-density tungsten alloy aircraft maintenance rivet rods manufactured by CTIA GROUP LTD have many advantages, including material properties, manufacturing processes and maintenance efficiency. These advantages make it an indispensable tool in aircraft maintenance work, which can improve the quality of connections, repair speed, reduce costs, and enhance maintenance safety. Due to the customizability of high-density tungsten alloy, it can also adapt to the needs of different repair tasks, providing flexibility and versatility. In the aircraft maintenance industry, the high-density tungsten alloy rivet rods manufactured by CTIA GROUP LTD have achieved remarkable success, bringing significant improvements to aircraft maintenance work.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595