High-density tungsten alloy radiation shielding material is a special alloy material, usually composed of tungsten and some other alloy elements, used to effectively reduce or block the spread of radiation. Radiation can be electromagnetic radiation, such as X-rays and gamma rays, or particle radiation, such as neutron radiation. High-density tungsten alloy radiation shielding materials are widely used in medical, nuclear energy, scientific research, aerospace and other fields to protect personnel and equipment from harmful radiation. The reason this material is so important is because radiation is potentially harmful to both life and equipment, and effective shielding is needed to reduce its effects.

This article will explore in detail the properties, application areas, manufacturing processes and key role of high-density tungsten alloy radiation shielding materials in different industries.

Table of contents:

1 Introduction

- Properties of high-density tungsten alloy

2.1. Density

2.2. Plateau stability

2.3. High melting point

2.4. High hardness

2.5. Corrosion resistance

2.6. Non-magnetic

- Radiation hazards and shielding principles

3.1. Types of radiation

3.2. Hazards of radiation

3.3. Principles of radiation shielding

- Manufacturing process of high-density tungsten alloy radiation shielding materials

4.1. Alloy formula

4.2. Powder metallurgy preparation

4.3. Sintering

4.4. Alloy forming

- Application fields of high-density tungsten alloy radiation shielding materials

5.1. Medical field

5.2. Nuclear energy field

5.3. Scientific research fields

5.4. Aerospace field

5.5. Industrial sector

- Advantages and limitations of high-density tungsten alloy radiation shielding materials

6.1. Advantages

6.2. Limitations

- Future Outlook

- Conclusion

1 Introduction

Radiation is a ubiquitous natural phenomenon, which includes electromagnetic radiation and particle radiation. Electromagnetic radiation, such as X-rays and gamma rays, has high energy and poses a potential threat to living organisms and equipment. Particle radiation such as neutron radiation is also dangerous. Radiation can come from a variety of sources, including medical devices, nuclear reactors, space radiation, and industrial applications.

To protect personnel and equipment from the hazards of radiation, scientists and engineers have developed various radiation shielding materials. Among them, high-density tungsten alloy radiation shielding material is a popular choice because it has a series of excellent properties, including high density, high melting point, high hardness, corrosion resistance and non-magnetic properties.

This article will discuss in detail the properties, manufacturing processes, application fields of high-density tungsten alloy radiation shielding materials and its key role in different fields.

- Properties of high-density tungsten alloy

High-density tungsten alloy is a special material with several outstanding properties, making it ideal for radiation shielding.

2.1. Density

The most notable feature of high-density tungsten alloy is its extremely high density. Typically, the density of high-density tungsten alloys is above 16 grams per cubic centimeter (g/cm³), which is much higher than most common materials such as steel and aluminum. This property makes high-density tungsten alloys extremely effective radiation shielding materials because radiation particles require more material to penetrate, thereby reducing the likelihood of radiation transmission.

2.2. High melting point

The melting point of high-density tungsten alloy is very high, about 3422 degrees Celsius (℃), which allows it to maintain its structural integrity in high-temperature environments. In radiation shielding applications, this high melting point property is extremely valuable because it allows the material to continue to effectively shield radiation at high temperatures.

2.3. High hardness

High-density tungsten alloys also have high hardness. This makes it resistant to scratches and scuffs, maintaining its performance over long periods of use. This is very helpful in applications where radiation shielding equipment requires frequent movement or contact.

2.4. Corrosion resistance

High-density tungsten alloys generally have good corrosion resistance. This means that it can be used in various environments for a long time without being affected by chemical corrosion. This is particularly important for radiation shielding materials used in the medical, nuclear and industrial sectors.

2.5. Non-magnetic

High-density tungsten alloy is a non-magnetic material and will not be disturbed by magnetic fields. This is useful in applications such as scientific research equipment and MRI, where magnetic fields can interfere with measurements.

In summary, high-density tungsten alloys have a range of excellent physical and chemical properties that make them excellent radiation shielding materials.

- Radiation hazards and shielding principles

Before we delve into high-density tungsten alloy radiation shielding materials, we need to understand the types of radiation, the hazards, and the basic principles of shielding.

3.1. Types of radiation

Radiation can be divided into two main types:

- Electromagnetic radiation: This radiation consists of electromagnetic waves, including visible light, X-rays, gamma rays, radio frequency radiation, etc. Among them, X-rays and gamma rays are the most energetic and penetrating types of radiation, so they are highly harmful to the human body and equipment.

- Particle radiation: This radiation is composed of charged particles, such as alpha particles, beta particles and neutrons. Particle radiation may also be harmful to life and equipment under certain circumstances.

3.2. Hazards of radiation

Radiation is potentially harmful to life and equipment. It can cause the following problems:

- Cell damage: High-energy radiation such as X-rays and gamma rays can damage DNA and other molecular structures within cells, leading to cell death or mutation. This can lead to cancer and other serious health problems.

- Biological effects: Radiation can cause biological effects such as radiation sickness, acute radiation syndrome, etc.

- Equipment damage: Radiation can also adversely affect electronic equipment and circuits, causing them to degrade or malfunction.

- Radiation contamination: The leakage or improper handling of radioactive materials can lead to radiation contamination, causing long-term harm to the environment.

3.3. Principles of radiation shielding

The basic principle of radiation shielding is to place materials between the radiation source and the radiated object to reduce the transmission and scattering of radiation. Material selection is a key factor, as different materials have different shielding effectiveness against different types of radiation.

For electromagnetic radiation, such as X-rays and gamma rays, high-density materials are ideal because they absorb and scatter the radiation efficiently. This absorption and scattering results in a loss of radiated energy, thereby reducing the likelihood of radiation transmission. High-density tungsten alloys are widely used in these applications due to their extremely high density and other physical properties.

Shielding from particle radiation is more complex because it usually requires the use of materials to absorb and stop the charged particles. This type of shielding may involve more complex materials and structural design.

- Manufacturing process of high-density tungsten alloy radiation shielding materials

The manufacturing process of high-density tungsten alloy radiation shielding materials typically involves the following steps:

4.1. Alloy formula: The first step in manufacturing high-density tungsten alloy is to determine the composition of the alloy. Usually, high-density tungsten alloy is composed of tungsten and other alloying elements such as nickel, iron, etc. The proportions of these elements affect the material’s properties.

4.2. Powder metallurgy preparation: Alloying elements are usually mixed together in powder form to form uniform alloy powder. This can be achieved by methods such as mechanical alloying or chemical synthesis.

4.3. Sintering: Alloy powders are usually sintered at high temperatures to compress them into a solid block. During the sintering process, the powder particles bond to each other to form a uniform material structure.

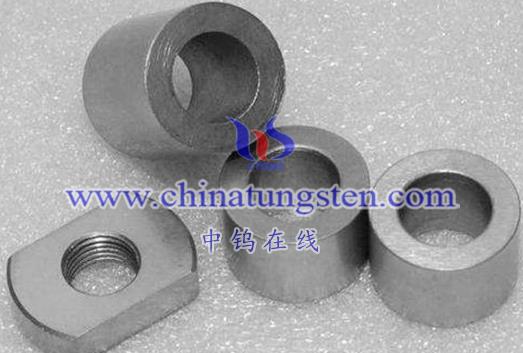

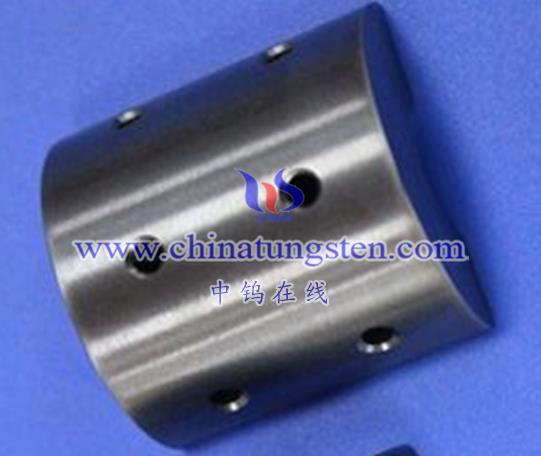

4.4. Alloy shaping: The sintered high-density tungsten alloy block can be further processed into the required shape

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595