High-Density Tungsten Alloy Radiation Shielding Materials are a type of special material, usually made of high-density tungsten alloy, designed to provide effective radiation shielding properties to protect personnel, equipment and the environment from Radiation hazards. These materials are widely used in various fields such as the medical field, nuclear energy industry, industrial applications, scientific experiments, and aerospace to reduce or absorb radiation from different types of radiation sources. In this article, the definition, properties, preparation methods, application fields and importance of high-density tungsten alloy radiation shielding materials in different industries will be discussed in detail.

Part 1: Definition and basic properties of high-density tungsten alloy radiation shielding materials

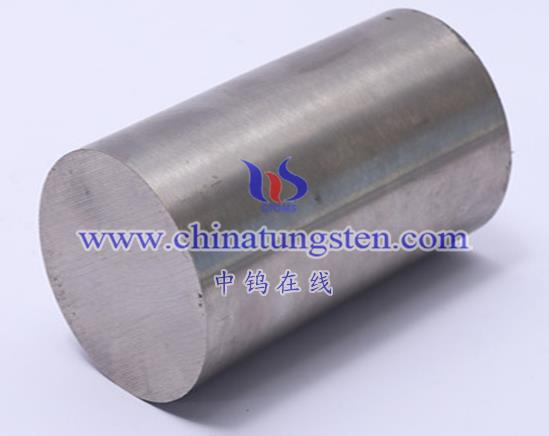

1.1 Definition of high-density tungsten alloy High-density tungsten alloy is a special alloy, usually composed of tungsten (W) as the main component, supplemented by a certain amount of elements such as nickel (Ni) and iron (Fe). This alloy is called “high density” because it is much denser than most other metallic materials. Generally speaking, the density of high-density tungsten alloys ranges from 16.5 grams per cubic centimeter (g/cm³) to 18.75 g/cm³, depending on the specific alloy formulation.

1.2 Basic properties High-density tungsten alloys have several significant properties that are critical to their application as radiation shielding materials. Here are some key properties:

1.2.1 High density: As its name suggests, the most significant feature of high-density tungsten alloy is its high density. This means it has an excellent ability to absorb radiation with quality, making it an ideal radiation shielding material.

1.2.2 High absorption capacity: High-density tungsten alloy can effectively absorb different types of radiation, including X-rays, gamma rays, neutron radiation, particle radiation, etc. This makes it a critical material in medical, nuclear energy, scientific research and other fields.

1.2.3 Corrosion resistance: High-density tungsten alloys usually have good corrosion resistance, which allows them to maintain their performance in a variety of environments. This is especially important for long-term use and multiple cycles.

1.2.4 Mechanical properties: High-density tungsten alloy has excellent mechanical properties, including high hardness, tensile strength and wear resistance. These properties make it more durable and suitable for use in a variety of applications.

1.2.5 Non-magnetic: High-density tungsten alloy is generally non-magnetic, which means that it will not be disturbed by magnetic fields. This is important for applications where magnetic field stability needs to be maintained, such as in medical imaging.

Part 2: Preparation method of high-density tungsten alloy radiation shielding materials

2.1 Material Formula The formula of high-density tungsten alloy can be adjusted according to specific application requirements. Typically, it is primarily composed of tungsten (W), while nickel (Ni) and iron (Fe) are used to increase processability and improve material properties. Depending on the formulation, other elements such as copper (Cu) and silver (Ag) can also be added to further tailor performance.

2.2 Preparation process The preparation of high-density tungsten alloy usually involves the following main process steps:

2.2.1 Preparation of raw materials: First, it is necessary to obtain high-purity tungsten powder and metal powder with alloy components. These powders are usually mixed in a ball mill to ensure even distribution.

2.2.2 Powder metallurgy: Heat the mixed metal powder to high temperature to melt and mix it evenly. The metallic liquid is then solidified into a uniform mass through rapid cooling.

2.2.3 Powder metallurgy sintering: The prepared powder metallurgy block usually goes through a sintering process, which is to heat it to a temperature close to the melting point to eliminate pores and increase the density of the material. This helps achieve the high density required.

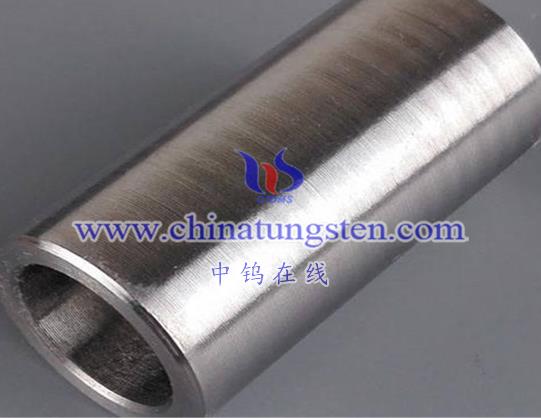

2.2.4 Precision processing: The prepared high-density tungsten alloy block usually requires further precision processing, such as cutting, drilling and grinding, to meet specific size and shape requirements.

2.2.5 Surface treatment: The surface of high-density tungsten alloy materials can be treated to improve its corrosion resistance and mechanical properties.

2.3 Customized preparation Since the formula and preparation process of high-density tungsten alloy materials have a certain degree of flexibility, they can be customized according to the requirements of specific applications. This includes adjusting alloy recipes and preparing materials in different shapes and sizes to meet different radiation shielding needs.

Part 3: Application fields of high-density tungsten alloy radiation shielding materials

High-density tungsten alloy radiation shielding materials are widely used in various fields and are mainly used to provide effective radiation protection. Here are some of the main application areas:

3.1 Medical field In the medical field, high-density tungsten alloy radiation shielding materials are used for a variety of purposes, including:

3.1.1 Radiation diagnosis: X-rays and gamma rays are common radiation sources in medical imaging tools such as X-ray tomography (CT) and radiotherapy. High-density tungsten alloy can be used to make X-ray protective clothing, radiation protection walls and shielding equipment to protect medical staff and patients from radiation damage.

3.1.2 Radiation therapy: In tumor treatment, radiation therapy equipment produces radiation to destroy cancer cells. High-density tungsten alloys are used in the manufacture of treatment helmets, radiation shielding walls and treatment rooms to ensure that radiation only reaches the target area of the patient.

3.1.3 Nuclear Medicine: Nuclear medicine imaging uses radioactive isotopes for molecular imaging. High-density tungsten alloy is used to manufacture radiation shielding containers to ensure that operators are not affected by radiation.

3.2 Nuclear energy field The nuclear energy industry involves the use of nuclear reactors and nuclear radiation equipment, which produce large amounts of radiation. High-density tungsten alloys are used in reactor casings, radiation shielding structures and nuclear waste containers to protect workers and the environment from radiation hazards.

3.3 Industrial applications In the industrial field, high-density tungsten alloy radiation shielding materials are used for the following purposes:

3.3.1 Radiation detection: Equipment used for the detection of radioactive materials, such as X-ray detection and radiation detectors, usually require radiation shielding to protect the operator and the surrounding environment.

3.3.2 Radiation Encapsulation: In some industrial applications, radioactive materials need to be encapsulated in high-density tungsten alloy containers to reduce radiation leakage.

3.3.3 Radiation Control: Some industrial processes produce radiation, and high-density tungsten alloys are used in the design and construction of radiation shielding structures to reduce workers’ radiation exposure.

3.4 Scientific experiments Scientific laboratories use high-density tungsten alloy radiation shielding materials to protect experimenters from the radiation hazards generated during experiments. This includes particle physics experiments, nuclear reaction experiments, and other high-energy physics experiments.

3.5 Aerospace In the aerospace sector, pilots and astronauts need to be protected from radiation, especially during long-duration space missions. High-density tungsten alloys are used to make space bulkheads and radiation shielding materials for space suits to reduce the harm of space radiation to personnel.

Part 4: The importance of high-density tungsten alloy radiation shielding materials

High-density tungsten alloy radiation shielding materials are important in various fields, and their importance is mainly reflected in the following aspects:

4.1 Protecting personnel health In the fields of medical treatment, nuclear energy, industry and scientific experiments, workers often need to be exposed to radiation sources. High-density tungsten alloy radiation shielding materials can effectively reduce their radiation exposure, thereby protecting their health.

4.2 Protecting the environment Radiation generated from nuclear energy and some industrial applications also poses potential risks to the environment. High-density tungsten alloy radiation shielding material is used to reduce radiation leakage and help protect the natural environment.

4.3 Improving medical imaging quality In the medical field, high-density tungsten alloy radiation shielding materials are not only used to protect medical staff and patients, but also to optimize imaging quality. It reduces scattered radiation and improves image clarity.

4.4 Promote scientific research High-density tungsten alloy radiation screens are needed in scientific laboratories and large scientific facilities. . . . . .

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595