High-density tungsten alloy can be used to manufacture a variety of key components in satellite balance parts to achieve satellite mass distribution and stability. The following are some common types of high-density tungsten alloys used in satellite balance components:

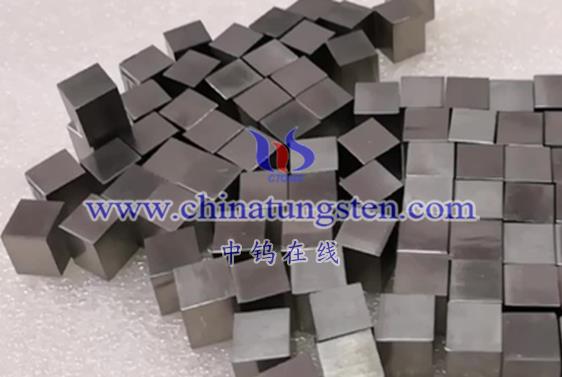

- Mass block: High-density tungsten alloy mass block is widely used in satellite balance control systems to adjust and distribute the mass of satellites. The blocks can be installed inside or outside the satellite structure to meet specific balancing needs.

- Gimbal: A gimbal is a ring-like structure on a satellite, usually made of high-density tungsten alloy to provide additional mass distribution and balance. The position and mass of the gimbal can be adjusted according to the design requirements of the satellite.

- Balance mass: In different parts of the satellite, high-density tungsten alloy balance masses may be needed to adjust the mass distribution to ensure the stability and performance of the satellite in orbit.

- Inertia wheel block: The satellite’s inertia wheel system usually requires a balance block to adjust the mass distribution of the wheel to ensure the rotation and stability of the wheel.

- Balance rod: The balance rod is used to balance the mass distribution of the satellite and is usually made of high-density tungsten alloy to provide the required balance and stability.

These high-density tungsten alloy balance parts play an important role in satellite design, helping to ensure the stability and performance of the satellite in orbit. The high-density properties of high-density tungsten alloy make it an ideal material for adjusting and optimizing satellite mass distribution without taking up too much satellite volume.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595