The plasticity and toughness of high-density alloys depend on factors such as their composition, preparation process and heat treatment system.

Generally speaking, high-density alloys have good plasticity and can withstand general processing deformations, such as tension, compression, bending, etc. This allows high-density alloys to be processed and formed through forging, rolling, extrusion and other processes.

In terms of toughness, the toughness of high-density alloys depends on their composition and microstructure. Some high-density alloys, such as tungsten-nickel-iron alloy, have good toughness and can withstand loads such as shock and vibration. However, for some alloys containing more brittle phases, their toughness may be poor and brittle fracture may occur easily.

In order to improve the plasticity and toughness of high-density alloys, some special preparation processes and heat treatment systems can be used. For example, the plasticity and toughness of the alloy can be improved by refining the alloy’s grain size, optimizing the alloy’s composition and phase composition, and performing appropriate heat treatments.

To sum up, the plasticity and toughness of high-density alloys depend on factors such as their composition, preparation process and heat treatment system. For specific application scenarios, appropriate high-density alloys can be selected according to actual needs and processed and heat treated accordingly to obtain the required plasticity and toughness.

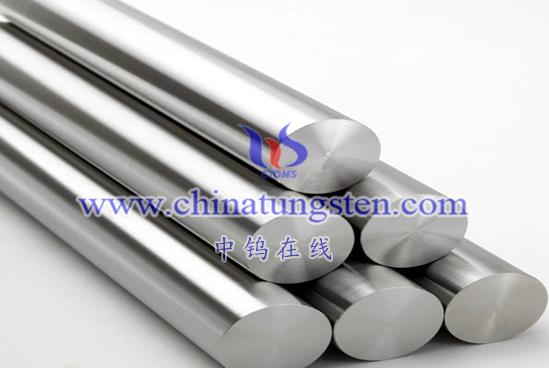

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595