The following factors need to be considered during the design and manufacturing process of high-density alloys:

- Component selection: The component selection of high-density alloys is key because it directly affects the physical and mechanical properties of the alloy. Commonly used alloying elements include tungsten, molybdenum, iron, nickel, copper, aluminum, etc. At the same time, the density, strength, hardness, wear resistance and corrosion resistance of the alloy need to be considered.

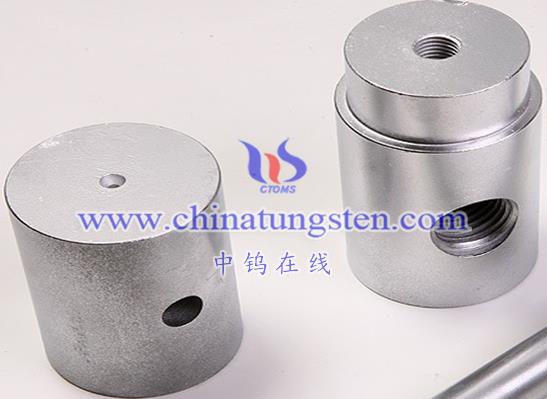

- Preparation process: The preparation process of high-density alloy has a great impact on its performance. Commonly used preparation processes include powder metallurgy, smelting and casting. The powder metallurgy process has the advantages of preparing high-density alloys. For example, there is no need to melt metal during the preparation process, and parts with complex shapes can be prepared.

- Heat treatment: Heat treatment is an important step in the preparation process of high-density alloys. It can change the internal structure of the alloy, improve its strength and hardness, while maintaining good plasticity and toughness. Parameters such as appropriate heat treatment temperature, time and cooling rate need to be selected.

- Mechanical properties: High-density alloys need to have certain mechanical properties, such as strength, hardness, wear resistance, corrosion resistance and toughness. These properties are affected by factors such as the alloy’s composition, preparation process and heat treatment.

- Processing and forming: High-density alloy has good processability and formability, and can be used for turning, milling, drilling, stamping and other processing operations. During the machining process, attention needs to be paid to controlling parameters such as temperature, speed, and tool selection to avoid problems such as cracks and deformation.

- Environmental protection and safety: Environmental protection and safety issues need to be considered during the production and application of high-density alloys. It is necessary to choose alloy elements and preparation processes that are harmless to the human body and the environment, and at the same time, attention needs to be paid to the treatment and recycling of waste materials and waste.

To sum up, factors such as ingredient selection, preparation process, heat treatment, mechanical properties, processing and forming, as well as environmental protection and safety need to be considered during the design and manufacturing process of high-density alloys. It is necessary to select appropriate alloy materials and preparation processes based on actual application scenarios, and strictly control various parameters during the production process to ensure the quality and reliability of high-density alloys.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595