High-density alloys are relatively expensive to manufacture.

On the one hand, the composition of high-density alloys usually includes high-value elements such as tungsten and molybdenum, and the cost of these elements is relatively high. At the same time, the manufacturing process of high-density alloys usually requires the use of special processes, such as powder metallurgy, smelting and casting, etc., and the manufacturing costs of these processes are also relatively high.

On the other hand, the manufacturing process of high-density alloys requires the control of various parameters, such as temperature, time and cooling rate. The control of these parameters requires precise operations and equipment, which also increases manufacturing costs.

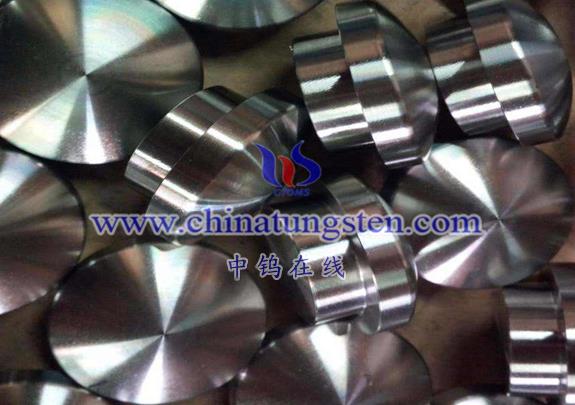

However, high-density alloys have excellent physical and mechanical properties, such as high density, high strength, high hardness, wear resistance and corrosion resistance, etc. These properties make them irreplaceable in some fields. For example, in many fields such as the electronic industry, medical field, military field and financial field, high-density alloys are widely used in the manufacture of electronic components, circuit boards, computer casings and other products.

Therefore, although the manufacturing cost of high-density alloys is relatively high, in some specific application scenarios, it has an irreplaceable role and value.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595