The mechanism of fatigue crack initiation and propagation in high-density alloys is a complex process involving many factors, including the mechanical properties of the material, stress level, number of cycles, temperature, humidity, etc.

First of all, the mechanism of fatigue crack initiation is the process of gradual expansion of cracks in the material when the material is subjected to repeated stress. This process has obvious cyclic nature, that is, the material undergoes slight deformation and displacement under cyclic loading, resulting in tiny cracks on the surface of the material. As the number of cycles increases, these tiny cracks will gradually expand and eventually lead to material fatigue failure.

The main cause of fatigue crack initiation is microscopic defects in the material. These defects may be pores, inclusions, grain boundaries, etc. in the material. When the material is subjected to stress, these defects accelerate the initiation and propagation of cracks. In addition, the mechanical properties of materials such as hardness, toughness and elastic modulus also affect the initiation and propagation of cracks. Generally speaking, the harder the material, the slower the initiation and propagation of cracks, while the opposite is true for the tougher material.

In addition to microscopic defects and the mechanical properties of the material, factors such as environmental temperature and humidity can also affect the initiation and expansion of cracks. For example, in high temperature environments, the creep properties of materials will change, thus affecting the initiation and propagation of cracks. In addition, an environment with high humidity may cause corrosion and damage to materials, thereby accelerating the initiation and expansion of cracks.

In summary, the mechanism of fatigue crack initiation and propagation in high-density alloys is a complex process involving multiple factors. In order to better understand and control this process, further research and exploration of the effects and mechanisms of various factors are needed.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

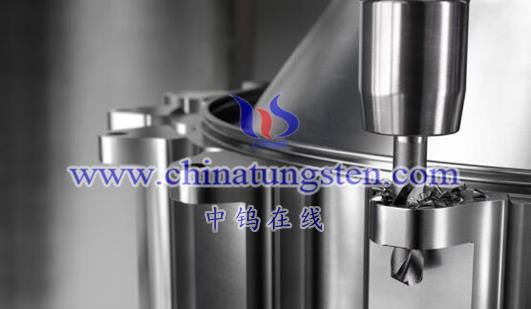

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595