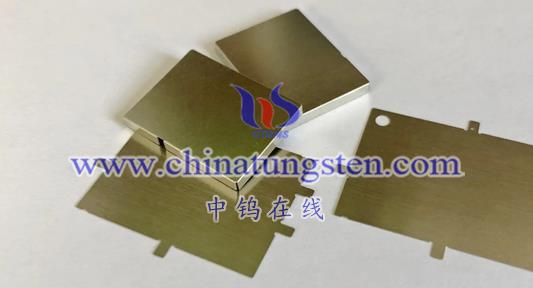

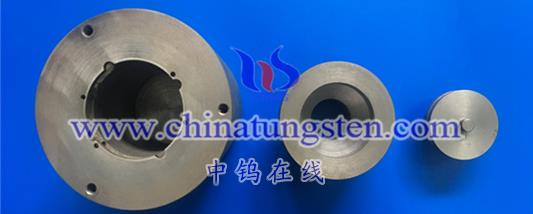

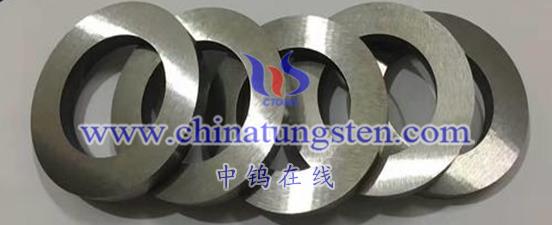

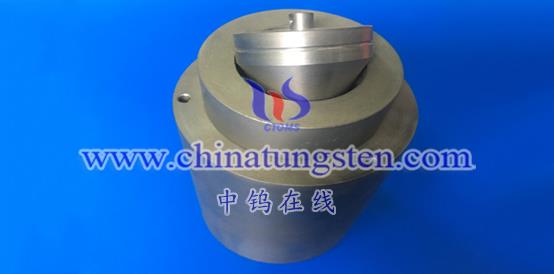

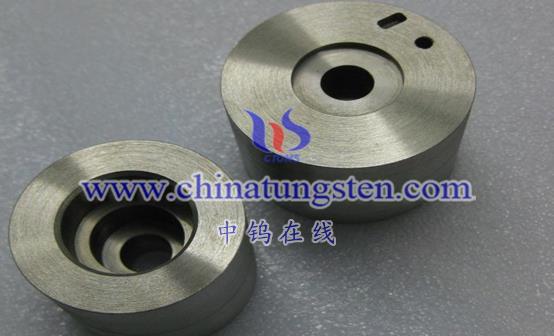

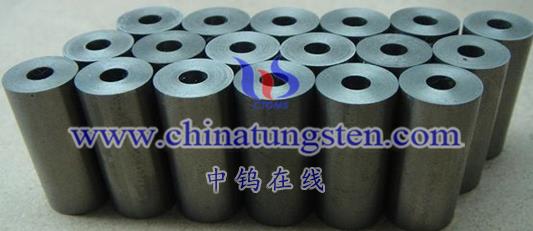

High-density tungsten alloy radiation shielding component is a radiation shielding component made of high-density tungsten alloy material. This kind of component usually has the characteristics of high density, high strength, high hardness, excellent wear resistance and toughness, so it is widely used in the nuclear industry, medical and other fields.

In the manufacturing process of high-density tungsten alloy radiation shielding components, tungsten and other metallic or non-metallic elements are usually alloyed using methods such as powder metallurgy or liquid phase sintering. These alloys have properties such as high density, high strength, high hardness, excellent wear resistance and toughness, allowing the manufacture of radiation shielding components with excellent properties.

High-density tungsten alloy radiation shielding components have a wide range of applications, including but not limited to the following aspects:

- Nuclear industry: High-density tungsten alloy radiation shielding components can be used to manufacture nuclear reactor shielding layers, control rod driving mechanisms, nuclear fuel transportation containers and other components to improve the radiation shielding effect and safety of nuclear facilities.

- Medical field: High-density tungsten alloy radiation shielding components can be used to manufacture radiation protection devices for medical equipment, such as medical accelerators, radiotherapy equipment, etc., to protect the safety of medical staff and patients.

- Aerospace field: High-density tungsten alloy radiation shielding components can be used to manufacture radiation protection layers for spacecrafts, radiation protection devices for aircraft cockpits, etc., to improve the safety and reliability of aircraft.

- Military field: High-density tungsten alloy radiation shielding components can be used to manufacture missile guidance hoods, radar antennas and other components to improve the performance and reliability of military equipment.

- Civil construction field: High-density tungsten alloy radiation shielding components can be used to manufacture radiation protection walls of buildings, anti-radon gas leakage layers in basements, etc., to protect the health and safety of residents.

- Scientific research field: High-density tungsten alloy radiation shielding components can be used to manufacture laboratory radiation protection devices, structural parts of scientific research equipment, etc., to ensure the safety of scientific researchers and the accuracy of experimental results.

- Nuclear waste processing field: High-density tungsten alloy radiation shielding components can be used to manufacture nuclear waste storage containers, transportation vehicles and other equipment to improve the safety and reliability of nuclear waste processing.

In summary, high-density tungsten alloy radiation shielding components are an engineering material of great value, widely used in many fields, and have broad application prospects.

The following is some specific data support:

- High density: The density of tungsten alloy is usually higher than that of pure tungsten because the addition of other metal or non-metal elements increases its density. The high density makes tungsten alloy have high strength and stiffness, and can withstand greater pressure and impact. Depending on the composition and manufacturing process, the density of high-density tungsten alloys is usually between 15-22g/cm³.

- High strength: Due to the addition of other metal elements, tungsten alloy has high strength and hardness. At normal temperature, the tensile strength and yield strength of tungsten alloy are usually between 800-1500MPa, which is much higher than the strength of pure tungsten. In addition, tungsten alloy also has excellent wear resistance and toughness, and can maintain stable structure and performance under conditions of impact and friction.

- Excellent radiation resistance: High-density tungsten alloy has excellent radiation resistance and can effectively absorb and scatter various rays, such as X-rays, γ-rays, etc. This property makes tungsten alloy an ideal material for manufacturing radiation protection devices, guidance hoods and other components. In the medical field, high-density tungsten alloy can also be used to make collimators, beam limiters and other components of radiation therapy equipment to improve treatment accuracy and safety.

- Good oxidation resistance: Compared with other metal materials, tungsten alloy has stronger oxidation resistance and can maintain the stability of its structure and performance for a long time in high temperature environments. This characteristic gives tungsten alloy advantages in applications in aerospace, military and other fields, and can meet reliability requirements in harsh environments.

- Good electrical conductivity: High-density tungsten alloy has good electrical conductivity, and its electrical conductivity is close to that of pure copper. This property makes tungsten alloy widely used in manufacturing electronic components, circuit boards and other fields.

- Excellent corrosion resistance: Tungsten alloy has good corrosion resistance and can resist the erosion of various chemical substances. In a corrosive environment, a dense oxide film can be formed on the surface of tungsten alloy to prevent further corrosion. This characteristic makes tungsten alloy widely used in chemical industry, marine engineering and other fields.

- Good processing performance: Tungsten alloy has good processing performance and can be used for turning, milling, drilling and other processing operations, making it easy to manufacture parts of various shapes and sizes. This feature makes tungsten alloy less difficult and less expensive to manufacture, which is conducive to mass production. Good processing properties also enable tungsten alloys to meet the design requirements of various complex shapes and structures.

- Low evaporation rate: Compared with other metal materials, tungsten alloy has a low evaporation rate. This means that when used in high-temperature environments, tungsten alloys can maintain structural and performance stability for a longer period of time. This characteristic makes tungsten alloys of great value in high-temperature applications such as aerospace, nuclear industry and other fields.

- High thermal expansion coefficient: Compared with some metal materials, tungsten alloy has a higher thermal expansion coefficient. This means that the size of tungsten alloy changes greatly when the temperature changes.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595