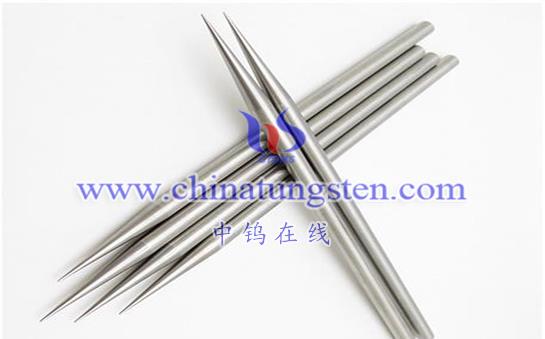

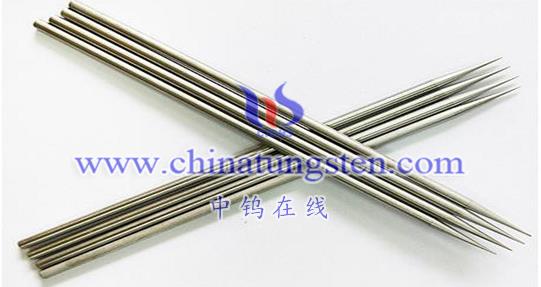

The surface of polished tungsten rod has a silver-gray metallic luster, no obvious oxidation phenomenon, and the surface is uniform without delamination, cracks, burrs, longitudinal cracks and other shortcomings. It has many excellent properties such as high density, high melting point, small size, extremely high wear resistance, extremely high hardness, high tensile strength, high elongation, high temperature resistance, etc., so it is mainly used in manufacturing gate side rod brackets. Lead wires, electrodes, tungsten bracelet point materials. Tungsten rods are divided into forged tungsten rods, sintered tungsten rods and polished tungsten rods. Through the rotation of a special grinding wheel (or belt) coated with abrasives, the surface of metal parts is cut to remove burrs, rust, scratches, weld nodules, welds, blisters, scale and other macroscopic Disadvantages to improve the flatness of parts. Polishing is suitable for processing all metal materials and some non-metal materials. The surface of the polished tungsten rod is smoother and crack-free, and the product quality is better. The polished tungsten rod prepared by Chinatungsten Online Technology Co., Ltd. has a uniform internal structure, fine grains, no cracks, no voids and good processing performance.

Medical tungsten materials have a tungsten purity of over 99.98%, are biocompatible, have excellent conductivity, electron emission capabilities, high density, and good radiation shielding properties. They can be used to customize key tungsten components for medical equipment manufacturers. Chinatungsten Online has the unique advantage of precision processing of refractory metals. The processing accuracy is controlled at 0.001mm. It can design and process tungsten and molybdenum parts according to drawings or samples, provide customers with diversified products and customized services, and provide customers with customized medical equipment. Use tungsten and molybdenum parts. Products are used in machinery manufacturing and welding, electric light sources and electric vacuum, semiconductors, medical industry, automobile industry, electrical appliance manufacturing, vacuum coating, new energy, environmental protection and other fields.

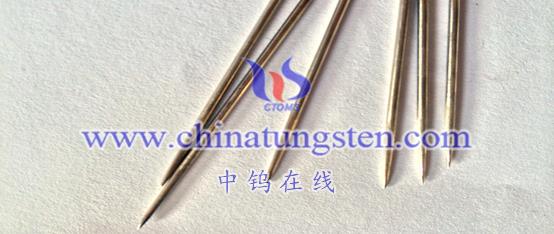

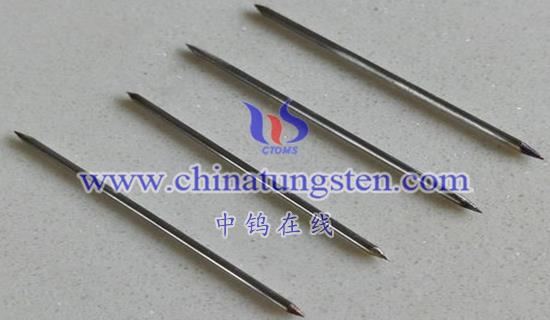

Double-ended sharpened tungsten needles can be pure grounded tungsten needles, tungsten alloy sharpened tungsten needles or rare earth doped grounded tungsten needles. Pure tungsten needle electrode has a high melting point, strong electron emission capability, high elastic modulus, and ablation resistance. It can be used in tungsten argon arc welding. It plays an important role in arc starting, arc stability and welding quality. play an important role. Rare earth-doped ground tungsten needle electrodes can improve the welding performance of pure tungsten electrodes and stimulate its electron work function, making them have better arc starting performance, higher arc column stability, and smaller electrode burning rate . The sharpened electrode is suitable for DCSP, that is, the tungsten needle electrode is connected to the negative pole of the power supply output, and the weldment is connected to the positive pole of the power supply.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595