Tungsten Alloy Collimator (Tungsten Alloy Collimator) is a device used to adjust and limit the direction of particle beams or ray beams. It is usually used in medical imaging, radiation therapy, nuclear physics experiments and other fields. Such devices are usually made of high-density tungsten alloys, which have excellent mass absorption properties and can effectively scatter or absorb rays. High-density tungsten alloy collimator is an important equipment used in the fields of radiographic detection, medical imaging and industrial non-destructive testing. It utilizes the characteristics of high-density tungsten alloy materials to achieve precise control and collimation of rays, improving imaging quality and detection accuracy.

- Composition of high-density tungsten alloy collimator

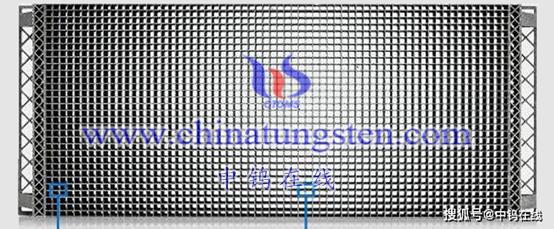

High-density tungsten alloy collimator is mainly composed of high-density tungsten alloy plates, support structures, sealing materials, etc.

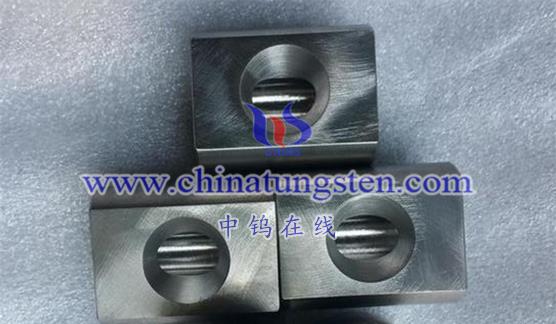

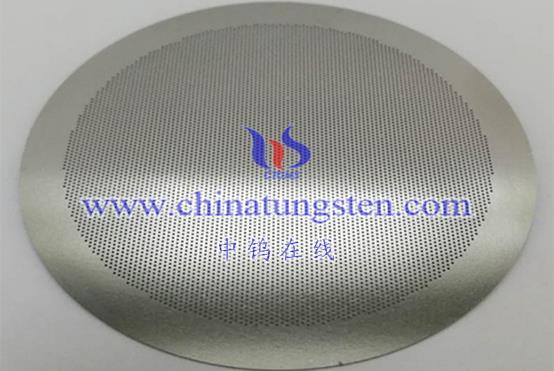

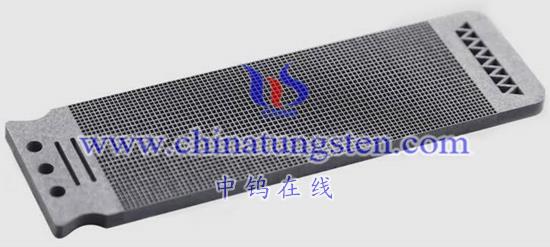

- High-density tungsten alloy plate: High-density tungsten alloy plate is the core component of the collimator. It has the characteristics of high density, high strength, high hardness, excellent wear resistance and toughness, and can effectively absorb and scatter rays. , achieving precise control and collimation of rays.

- Support structure: The support structure is the skeleton of the collimator. It can fix and support the tungsten alloy plate, and can also protect and support the collimator.

- Sealing material: Sealing material is mainly used to prevent leakage of the collimator. It can completely seal the space around the ray source to ensure that the rays will not leak out.

- Advantages of high-density tungsten alloy collimator

High-density tungsten alloy collimator has the following advantages:

- High density: High-density tungsten alloy materials have extremely high density and can effectively absorb and scatter rays, reducing the harm of rays to the surrounding environment and personnel.

- High strength: High-density tungsten alloy material has high strength, high hardness, excellent wear resistance and toughness, which can ensure the stability and durability of the collimator.

- Precise ray control: Through precise design and manufacturing, high-density tungsten alloy collimators can achieve precise control and alignment of rays, improving imaging quality and detection accuracy.

- Easy installation: The installation of high-density tungsten alloy collimators is quick and easy, and collimators of different specifications and shapes can be customized according to actual needs.

- Long service life: Due to the excellent corrosion resistance and wear resistance of high-density tungsten alloy materials, it has a long service life and can effectively protect the safety of personnel and equipment for a long time.

- Application scope of high-density tungsten alloy collimator

High-density tungsten alloy collimators are widely used in fields such as radiographic testing, medical imaging, and industrial non-destructive testing. Specific applications are as follows:

- Ray detection: In the field of radiation detection, high-density tungsten alloy collimators are used to precisely control and collimate rays to ensure that the rays can accurately illuminate the object to be detected and improve detection accuracy and efficiency. For example, in X-ray inspection, high-density tungsten alloy collimators can be used to control the direction and range of X-rays to avoid unnecessary radiation to other areas.

- Medical imaging: In the field of medical imaging, high-density tungsten alloy collimators are used to precisely control the direction and range of rays and improve imaging quality and resolution. For example, in CT scans, high-density tungsten alloy collimators can ensure that X-rays are accurately illuminated on the patient and obtain clear tomographic images.

- Industrial non-destructive testing: In the field of industrial non-destructive testing, high-density tungsten alloy collimators are used to control the direction and range of rays to achieve accurate detection and positioning of internal defects in industrial components. For example, in oil pipeline inspection, high-density tungsten alloy collimators can ensure that X-rays are accurately illuminated inside the pipeline to detect potential cracks, corrosion and other problems.

- Manufacturing process of high-density tungsten alloy collimator

The manufacturing process of high-density tungsten alloy collimators mainly includes the following steps:

- Ingredients: Ingredients are made according to the required high-density tungsten alloy composition and proportion.

- Smelting: Put the ingredients into a high-temperature furnace for smelting to form a high-density tungsten alloy base material.

- Rolling: The base material is rolled to form high-density tungsten alloy plates of the required specifications and shapes.

- Cutting: Cut the plate as required to form a tungsten alloy block of the required size.

- Assembly: Assemble the tungsten alloy blocks according to the design requirements to form a complete collimator structure.

- Inspection: Inspect the assembled collimator to ensure that it meets the design requirements and quality standards.

- Development trend of high-density tungsten alloy collimators

With the continuous development and advancement of science and technology, high-density tungsten alloy collimators will be developed in the following aspects:

- Material performance improvement: By improving manufacturing processes and increasing material purity, the performance and stability of high-density tungsten alloys will be further improved. This will help improve the service life and safety performance of the collimator.

- Structural optimization design: By optimizing the structure of the collimator, its impact resistance, fatigue resistance and other properties are improved, and its service life is extended. At the same time, collimators of different specifications and shapes can also be customized according to actual needs to meet the needs of different application scenarios.

- Intelligent manufacturing: Introduce advanced intelligent manufacturing technology to realize automated production and intelligent monitoring of high-density tungsten alloy collimators. This will help improve production efficiency and product quality consistency.

- Multi-functionality: Develop high-density tungsten alloy collimators with multiple functions, such as temperature regulation, explosion-proof and other functions, to improve their application range and effectiveness. This will help meet the needs of more complex application scenarios.

- Environmentally friendly production: Pay attention to environmental protection requirements during the production process, and use environmentally friendly materials and processes to reduce the impact on the environment. This will help promote the sustainable development of the collimator industry.

- Improved accuracy and resolution: As the requirements for imaging quality and resolution continue to increase in fields such as medical imaging and industrial non-destructive testing, the accuracy and resolution of high-density tungsten alloy collimators will also be further improved. This will help improve detection accuracy and reliability.

- Intelligent control: Introduce advanced intelligent control technology to realize remote monitoring and automatic adjustment of the collimator. This will help improve the automation and ease of operation of the equipment.

- Cost reduction: Reduce the manufacturing cost of high-density tungsten alloy collimators by optimizing manufacturing processes and material selection. This will help expand its application scope and improve market competitiveness.

In short, high-density tungsten alloy collimator is an important engineering material and has been widely used in fields such as radiographic testing, medical imaging, and industrial non-destructive testing. With the continuous development of science and technology, the performance and functions of high-density tungsten alloy collimators will be further improved, and the application fields will also continue to expand.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595