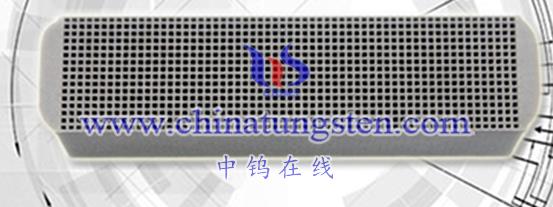

High-density tungsten alloy collimator is an engineering material with unique characteristics and is widely used in fields such as radiographic testing, medical imaging, and industrial non-destructive testing. The following is a detailed and comprehensive analysis of the characteristics of high-density tungsten alloy collimators:

- High density characteristics

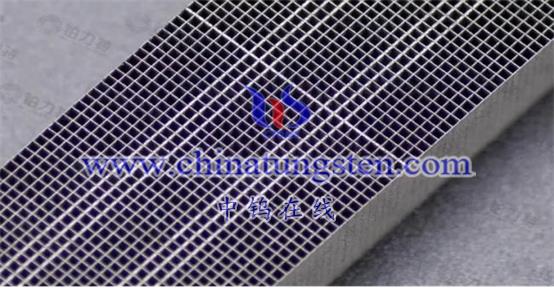

The extremely high density of high-density tungsten alloy collimators is one of its most significant features. Compared with other materials, tungsten alloy has a higher density, which allows it to effectively absorb and scatter various rays, reducing the harm of radiation to the surrounding environment and personnel. At the same time, the high density also improves the structural strength and stability of the collimator, allowing it to withstand larger pressure and temperature changes.

- Excellent physical properties

High-density tungsten alloy collimators have excellent physical properties, such as high strength, high hardness, excellent wear resistance and toughness. These characteristics allow the collimator to withstand large external forces and impacts while maintaining its shape and size stability. In addition, tungsten alloy also has good thermal and electrical conductivity, which helps improve the thermal stability and electrical performance of the collimator.

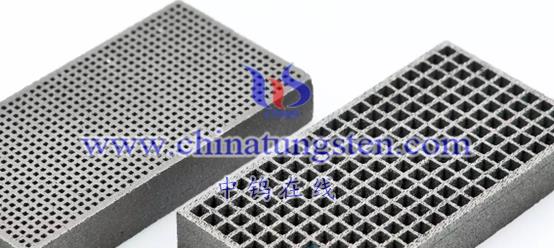

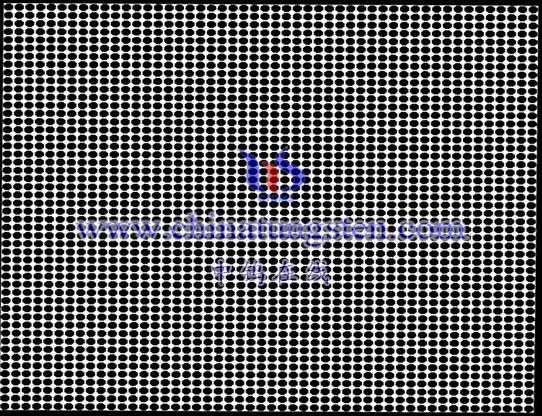

- Precise ray control

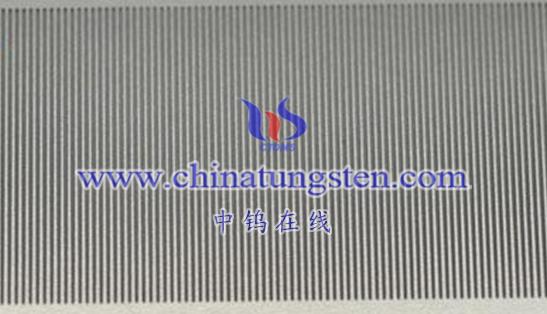

High-density tungsten alloy collimator enables precise control and collimation of rays. Through precise design and manufacturing, the collimator can accurately illuminate the rays emitted by the ray source onto the object to be detected, improving imaging quality and detection accuracy. At the same time, the high-density characteristics of tungsten alloy also help to reduce the scattering and reflection of rays and improve the utilization rate and detection efficiency of rays.

- Good corrosion resistance

High-density tungsten alloy collimators have good corrosion resistance and can be used for a long time in harsh environmental conditions. In fields such as medical imaging and industrial non-destructive testing, collimators need to be exposed to various chemicals and radiation environments, and the high corrosion resistance of tungsten alloys can ensure their long-term stable operation.

- Environmental protection

The manufacturing process of high-density tungsten alloy collimators pays attention to environmental protection requirements and uses environmentally friendly materials and processes. This helps reduce the impact on the environment and promotes the sustainable development of the collimator industry. At the same time, as a rare metal resource, the recycling and reuse of tungsten alloy is also of great significance.

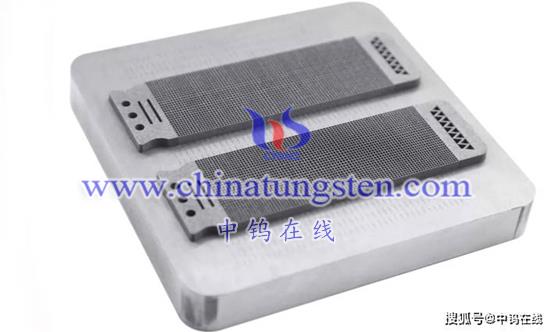

- Wide application fields

High-density tungsten alloy collimators are widely used in fields such as radiographic testing, medical imaging, and industrial non-destructive testing. In the field of radiation detection, collimators are used to control the direction and range of rays to improve detection accuracy and efficiency; in the field of medical imaging, collimators are used to accurately control the direction and range of rays to improve imaging quality and resolution; in the field of industrial non-destructive testing , the collimator is used to control the direction and range of rays to achieve accurate detection and positioning of internal defects in industrial components.

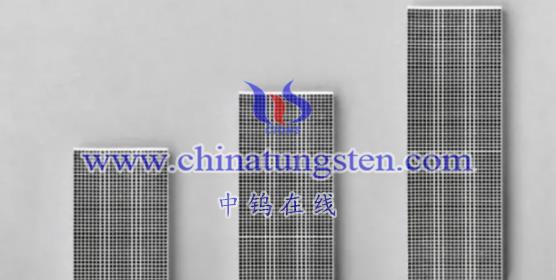

- Future development trends

With the continuous development and advancement of science and technology, the future development trend of high-density tungsten alloy collimators will be more diversified. First of all, the improvement of material properties will become one of the important directions for future research. Further improving the performance and stability of tungsten alloys by improving manufacturing processes and improving material purity will help improve the service life and safety performance of collimators. Secondly, structural optimization design will become one of the important directions for future research. By optimizing the structure of the collimator, it improves its impact resistance, fatigue resistance and other properties to extend its service life. Collimators of different specifications and shapes can also be customized according to actual needs to meet the needs of different application scenarios. In addition, intelligent manufacturing will also It has become one of the important directions for future development. The introduction of advanced intelligent manufacturing technology to realize automated production and intelligent monitoring of high-density tungsten alloy collimators will help improve production efficiency and product quality consistency. Finally, environmentally friendly production will also become a future development. One of the important directions is to pay attention to environmental protection requirements in the production process. Using environmentally friendly materials and processes to reduce the impact on the environment will help promote the sustainable development of the collimator industry. In summary, high-density tungsten alloy collimators have high density and excellent Characteristics such as physical properties, precise radiation control, good corrosion resistance, environmental protection, wide range of application fields, and future development trends make it one of the important engineering materials in the fields of radiographic testing, medical imaging, and industrial non-destructive testing.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595