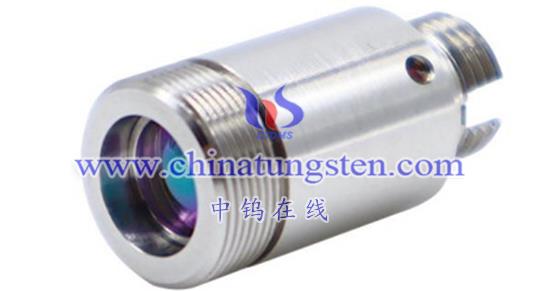

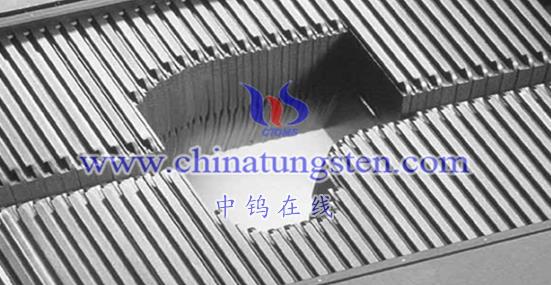

High-density tungsten alloy multi-leaf collimator is a device used to precisely control and adjust the direction and shape of a beam. It usually consists of multiple thin slices, each of which can be moved independently to change the shape and direction of the beam.

High-density tungsten alloy multi-leaf collimators have excellent properties such as high density, high strength, and high thermal stability. Therefore, they are widely used in applications that require precise control of beam shape and direction, such as laser processing, optical measurement, medical diagnosis, etc.

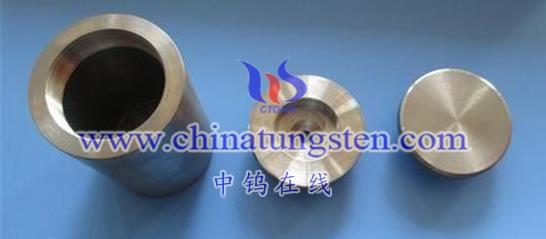

The manufacturing process of high-density tungsten alloy multi-leaf collimators usually includes steps such as smelting, casting, and heat treatment. During the smelting process, various metal elements need to be melted into a liquid alloy and the ingredients must be evenly distributed. During the casting process, liquid alloy is poured through a specific mold, where it is then cooled and hardened. During heat treatment, the alloy is heated and cooled to adjust its internal structure to obtain the desired physical and mechanical properties.

There are many types of high-density tungsten alloy multi-leaf collimators that can be customized according to different needs and uses. For example, parameters such as the number, thickness, and length of sheets of different specifications can be selected as needed. In addition, you can also choose different surface treatments, such as gold plating, silver plating, etc., to improve its reflectivity and corrosion resistance.

The main advantages of high-density tungsten alloy multi-leaf collimators include:

- High density: Tungsten alloy has high density and strength, so multi-leaf collimators with high precision and stability can be manufactured.

- High thermal stability: Tungsten alloy has high thermal stability and good corrosion resistance, so it can be used in high temperature environments and has a long service life.

- Precise control: The multi-leaf collimator can precisely control the shape and direction of the beam, so it can be used in applications that require high-precision control.

- Easy to operate: Multi-leaf collimators usually have simple operation methods, and the adjustment and positioning of the beam can be achieved through manual or automatic control.

In short, the high-density tungsten alloy multi-leaf collimator is a device with excellent performance and application prospects, and can be widely used in various applications that require precise control of beam shape and direction. With the continuous advancement of science and technology and the expansion of application fields, the application prospects of high-density tungsten alloy multi-leaf collimators will be broader.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595