High-density tungsten alloy is widely used in medical equipment, mainly in the following aspects:

- Radiotherapy equipment

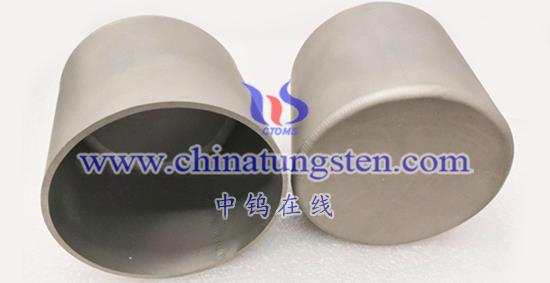

Radiation therapy is one of the important means of treating cancer and other diseases. High-density tungsten alloy plays an important role in radiotherapy equipment. First, tungsten alloys can be used to make containers for radioactive sources. Radioactive sources are key components in radiotherapy, and the high density and corrosion resistance of tungsten alloys make them an ideal material for manufacturing radioactive source containers. In addition, tungsten alloys can also be used to manufacture radiation shielding materials in treatment rooms to ensure that doctors and patients are protected from radiation damage.

Data support: The high density and good corrosion resistance of tungsten alloy enable it to withstand long-term radiation exposure and remain stable. At the same time, the excellent mechanical properties of tungsten alloy also enable it to meet the high-precision requirements of radiotherapy equipment.

- Medical imaging equipment

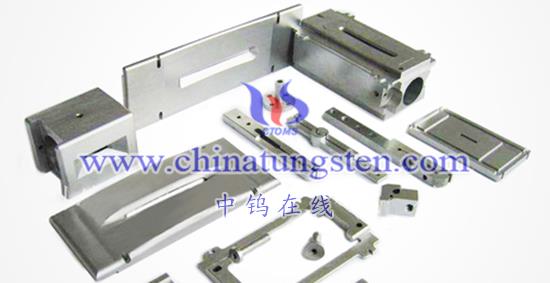

Medical imaging equipment is an important tool for medical diagnosis and treatment. High-density tungsten alloys are also widely used in medical imaging equipment. First of all, tungsten alloy can be used to manufacture scanning frames and support structures for CT, MRI and other equipment. These structures need to withstand the stress caused by the weight and movement of the equipment, while also requiring precise dimensions, stability and reliability. Tungsten alloy’s high strength and good corrosion resistance make it an ideal material for manufacturing these structures.

Data support: The high strength and good corrosion resistance of tungsten alloy enable it to withstand the weight of medical imaging equipment and the stress caused by movement and remain stable. At the same time, the excellent mechanical properties of tungsten alloy also enable it to meet the high-precision requirements of medical imaging equipment.

- Medical surgical instruments

High-density tungsten alloy can also be used to manufacture medical surgical instruments, such as scalpels, surgical needles, etc. These instruments require surgical operations in high temperature and high pressure environments, and are required to have excellent sharpness and corrosion resistance. Tungsten alloy’s high strength, hardness and good corrosion resistance make it an ideal material for manufacturing these devices.

Data support: The high strength, high hardness and good corrosion resistance of tungsten alloy enable it to meet the requirements of medical surgical instruments. At the same time, the excellent mechanical properties of tungsten alloy also enable it to withstand the complex stress environment during surgical operations.

- Support and fixed structures of medical devices

In medical devices, many components require precise support and fixation. High-density tungsten alloy is widely used in the support and fixation structures of medical devices due to its high strength and good corrosion resistance. For example, in medical imaging equipment, tungsten alloy can be used to manufacture the support structure of the scanning frame to ensure the stability and accuracy of the scanning frame. In surgical instruments, tungsten alloy can be used to manufacture the fixed structure of the scalpel to ensure the stability and safety of the scalpel during use.

Data support: The high strength and good corrosion resistance of tungsten alloy enable it to withstand the complex stress environment of the support and fixed structures of medical devices and remain stable. At the same time, the excellent mechanical properties of tungsten alloy also enable it to meet the high-precision requirements of medical devices.

- Parts and components of medical equipment

In addition to the above applications, high-density tungsten alloys can also be used to manufacture components for medical equipment, such as screws, nuts, bearings, etc. These parts need to be used for a long time in high temperature and high pressure environments, and are required to have excellent wear resistance and corrosion resistance. Tungsten alloy’s high strength, hardness and good corrosion resistance make it an ideal material for manufacturing these parts.

Data support: The high strength, high hardness and good corrosion resistance of tungsten alloy enable it to meet the requirements of components for medical equipment. At the same time, the excellent mechanical properties of tungsten alloy also enable it to withstand complex stress environments in long-term use.

In summary, high-density tungsten alloys have broad application prospects in medical equipment. It can not only be used to manufacture key components such as radiotherapy equipment, medical imaging equipment, and medical surgical instruments, but can also be used to manufacture supporting and fixing structures for medical equipment, as well as auxiliary components such as parts for medical equipment. With the continuous development and advancement of medical technology, the application of high-density tungsten alloys in medical equipment will become more extensive and in-depth.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595