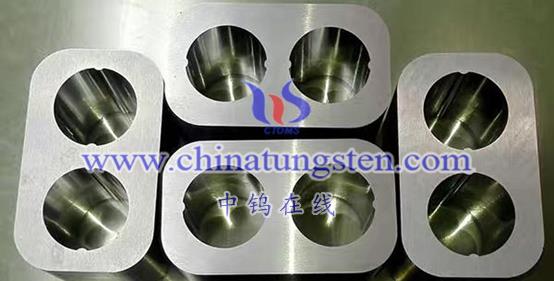

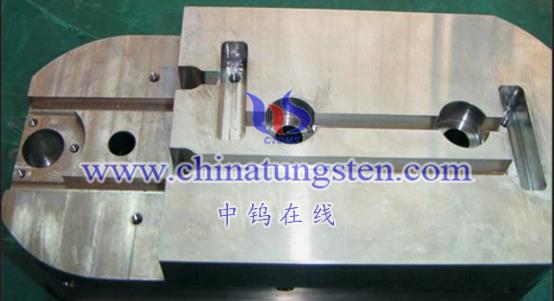

High-density tungsten alloys are difficult to process and manufacture. Due to its high hardness and density, problems such as edge chipping and wire breakage are prone to occur during processing. At the same time, the cutting force and friction are also large, resulting in prominent thermal deformation and thermal stress problems during processing. In addition, due to the high melting point, high hardness and brittleness of tungsten alloy, its processing technology is relatively complex and requires high equipment and personnel. Therefore, special processing techniques are required when processing and manufacturing high-density tungsten alloys, such as electric discharge machining, electrolytic machining, etc.

Although there are certain difficulties in processing and manufacturing high-density tungsten alloys, the accuracy and efficiency of its processing and manufacturing can be effectively improved by optimizing the processing technology, selecting appropriate equipment and tools, and optimizing cutting parameters. In addition, by using technologies such as rapid prototyping, high-density tungsten alloys can also be rapidly manufactured to meet the needs of different fields.

In short, although there are certain difficulties in processing and manufacturing high-density tungsten alloys, through reasonable process design and optimization measures, these difficulties can be overcome and its efficient and precise processing and manufacturing can be achieved.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595