- Definition and overview of high-density alloys

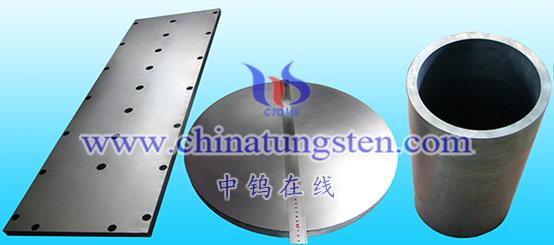

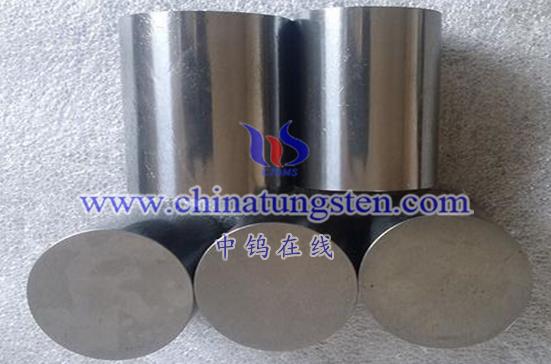

High-density alloys, as the name suggests, refer to alloy materials with higher density than conventional metals. This type of alloy is usually composed of two or more metal or non-metal elements and is processed through specific processes. High-density alloys have high physical density, excellent mechanical properties and chemical stability, and therefore are widely used in many fields.

- Composition and classification of high-density alloys

composition

High-density alloys are usually composed of two or more metallic elements, one of which is usually denser. In addition to metallic elements, non-metallic elements or compounds may be added to improve certain properties of the alloy.

Classification

According to the main constituent elements, high-density alloys can be divided into the following categories:

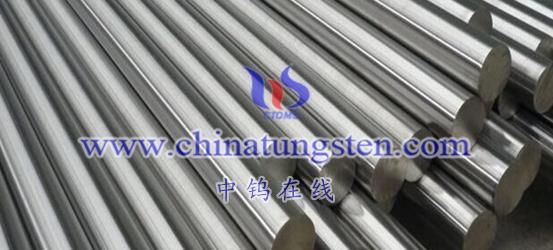

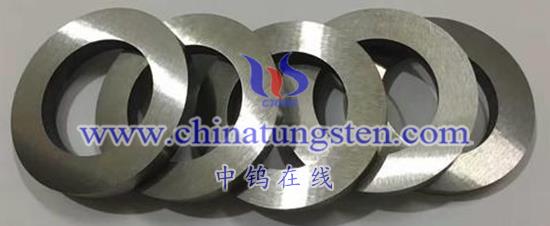

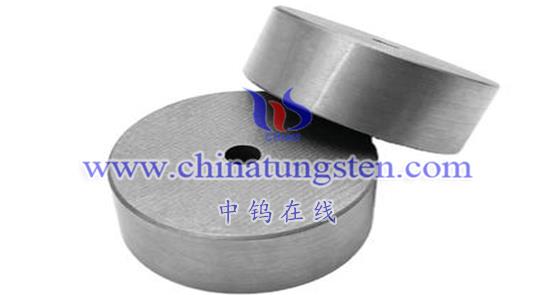

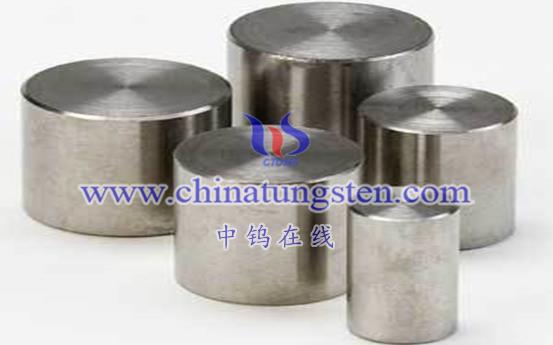

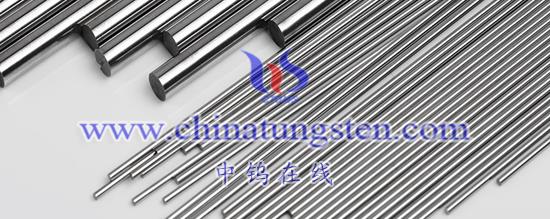

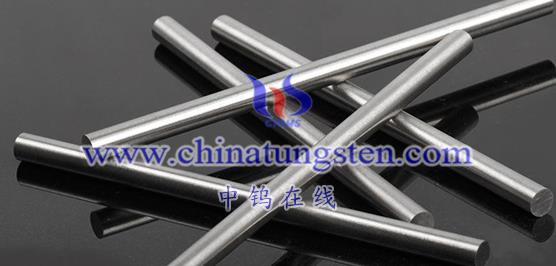

Tungsten-based high-density alloy: With tungsten as the main component, other metal elements such as nickel, iron, copper, etc. are added.

Molybdenum-based high-density alloy: with molybdenum as the main component, alloyed with other metal elements.

Niobium-based high-density alloy: a high-density alloy with niobium as the main component.

Other high-density alloys: such as lead-based, bismuth-based alloys.

- Properties of high-density alloys

physical properties

Density: The density of high-density alloys is usually greater than 10g/cm³, and the density of some alloys even exceeds 19g/cm³. For example, the density of tungsten alloy is usually between 15.6-19.3g/cm³.

Melting point: Since the metallic elements in high-density alloys usually have higher melting points, the melting points of such alloys are also relatively high.

mechanical properties

Hardness: High-density alloys generally have higher hardness, especially tungsten-based and molybdenum-based alloys.

Strength: This type of alloy is also very strong and can withstand large tensile and compressive stresses.

chemical properties

Corrosion resistance: Many high-density alloys have good corrosion resistance and can remain stable in harsh environments such as acids and alkalis.

Oxidation resistance: Some high-density alloys have good oxidation resistance at high temperatures.

- Preparation process of high-density alloy

Powder metallurgy: This is the main method for preparing high-density alloys. First, the required proportion of metal powder is prepared, and then the finished product is obtained through pressing, sintering and other processes.

Smelting method: smelting metal raw materials at high temperature, then casting and cooling to obtain alloy ingots.

Mechanical alloying method: Use high-energy ball milling technology to mix metal powders, and achieve atomic level mixing through cold welding and crushing during the ball milling process.

Other methods: Advanced technologies such as injection forming and 3D printing are also used in the preparation of high-density alloys.

- Expanded applications of high-density alloys

Electric vehicles and battery technology: With the rise of electric vehicles, there are higher requirements for the energy density and safety of batteries. High-density alloys have potential application value in battery positive and negative electrode materials, current collectors, and battery casings, which can improve the energy density and safety of batteries.

Deep Sea and Space Exploration: In deep sea and space exploration, equipment needs to withstand extreme pressures and environmental conditions. High-density alloys can be used to manufacture key components for deep-sea submersibles and space probes due to their high strength and good corrosion resistance.

Renewable energy: In the fields of renewable energy such as wind energy and solar energy, high-density alloys can be used to manufacture efficient and durable wind turbine blades, solar panel brackets, etc.

Environmental protection and waste disposal: With the improvement of environmental awareness, the requirements for waste disposal are also getting higher and higher. High-density alloys can be used to create efficient and durable waste treatment equipment such as crushers, compressors, etc.

3D printing technology: The rise of 3D printing technology provides more possibilities for the application of high-density alloys. Through 3D printing technology, high-density alloy products with complex shapes and excellent performance can be manufactured to meet personalized and customized needs.

- Challenges and development trends of high-density alloys

Challenges: Although high-density alloys have many excellent properties, they still face some challenges in practical applications, such as high manufacturing costs and difficult processing. In addition, with the improvement of environmental protection requirements, the use of harmful elements in alloys has also been restricted.

Development trend: In the future, the development of high-density alloys will proceed in the following directions: First, develop new high-density alloy materials to meet a wider range of needs; second, optimize the preparation process, reduce production costs and improve product quality; The third is to strengthen environmental protection research and reduce the use of harmful elements; the fourth is to expand application fields and open up new market space.

- The relationship between high-density alloys and the environment

Resource consumption: The manufacture of high-density alloys usually involves a variety of rare and precious metals, and the mining and refining of these resources puts a certain amount of pressure on the environment. Therefore, improving resource utilization and recycling are keys to reducing resource consumption.

Environmental impact: Some high-density alloys may produce harmful substances and waste gas and water during production and processing. In order to reduce the impact on the environment, strict environmental protection measures and cleaner production technologies need to be adopted.

Sustainable development: In order to achieve sustainable development of the high-density alloy industry, it is necessary to pay attention to the balance of resource conservation, environmental protection and economic benefits. Through technological innovation and management optimization, we will promote the development of the high-density alloy industry in a green and low-carbon direction.

- Research frontiers of high-density alloys

New alloy design: Use advanced computational simulation technology to design new high-density alloy materials with excellent properties. These materials may have higher strength, better corrosion resistance and a wider range of applications.

Advanced preparation technology: Develop efficient and precise preparation technologies, such as additive manufacturing (3D printing), powder metallurgy, etc., to achieve the manufacturing of high-density alloy products with complex shapes and high performance.

Research on the relationship between microstructure and properties: In-depth study of the relationship between microstructure and properties of high-density alloys to provide theoretical support for optimizing alloy composition and preparation processes.

Multifunctional research: Explore the multifunctional application of high-density alloys, such as the application of high-density alloy materials with both mechanical properties and electrical conductivity in electronic devices.

- Conclusion

As a unique metal material, high-density alloy plays an important role in many fields. With the advancement of science and technology and the continuous improvement of application requirements, the research and application of high-density alloys will continue to be deepened and expanded. At the same time, in the face of challenges such as resource consumption and environmental impact, active measures need to be taken to promote the sustainable development of the high-density alloy industry. Through technological innovation and management optimization, it is believed that high-density alloys will show their unique charm and value in more fields in the future.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595