Tungsten alloy is an alloy material composed of tungsten element and other metal elements. Tungsten is a metal element with high melting point, high density, high hardness, good electrical conductivity and corrosion resistance, so it is widely used in many fields. By adding other metal elements to tungsten alloy, the properties of tungsten can be improved and its application scope expanded.

- Composition and classification of tungsten alloy

- Composition: The main component of tungsten alloy is tungsten, usually accounting for more than 80%. Other metal elements such as iron, nickel, copper, cobalt, etc. are added as alloying elements to improve the properties of the alloy.

- Classification: According to different alloying elements, tungsten alloy can be divided into many types, such as tungsten ferroalloy, tungsten-nickel alloy, tungsten-copper alloy, etc. Different types of tungsten alloys have different performance characteristics and application ranges.

- Preparation process of tungsten alloy

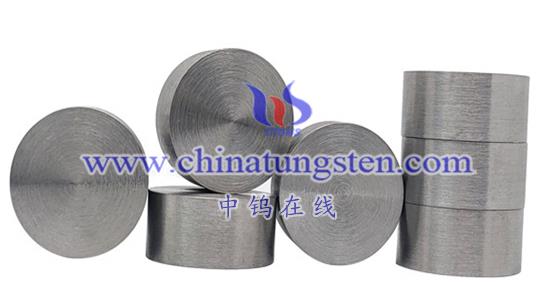

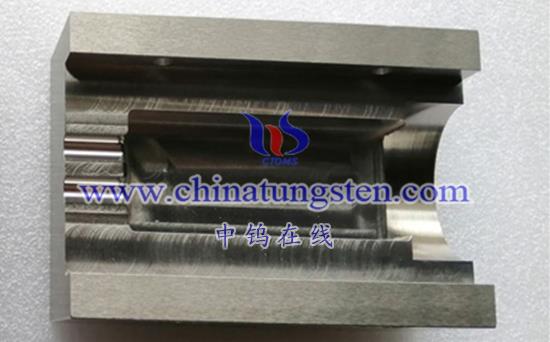

- Powder metallurgy: Powder metallurgy is the main method for preparing tungsten alloys. First, tungsten powder and alloying element powder are mixed evenly in a certain proportion, and then through pressing, sintering and other processes, the mixed powder is made into tungsten alloy products of the required shape.

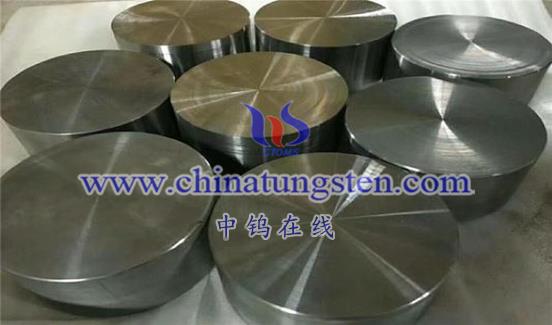

- Smelting method: The smelting method is to melt tungsten and alloying elements at high temperature, and then cool and solidify to obtain tungsten alloy. This method is suitable for preparing larger-sized tungsten alloy products.

- Mechanical alloying method: The mechanical alloying method uses high-energy ball milling and other methods to make tungsten powder and powder of alloying elements undergo an alloying reaction under the action of mechanical force, thereby obtaining tungsten alloy.

- Properties of tungsten alloy

Tungsten alloy is made of tungsten, chromium, iron, boron, titanium or tin and other metals mixed in a certain proportion. It has the characteristics of high melting point, high wear resistance and high hardness. The chemical properties of tungsten alloy are mainly reflected in the following aspects:

- High melting point: The melting point of tungsten alloy can be as high as 3000°C, which allows it to maintain stable performance in high temperature environments.

- Good corrosion resistance: Tungsten alloy can resist corrosion from most liquids and has good chemical stability.

- Good electromagnetic properties: can be used to manufacture electronic components such as electronic components and magnetrons.

Tungsten alloy is a comprehensive high-tech material that is widely used in aerospace, military industry, petrochemical industry, metal processing and other fields.

- Performance characteristics of tungsten alloy

- High density: The density of tungsten alloy is usually between 15.6-19.3g/cm³, which is much higher than other common metals. This gives tungsten alloy unique advantages in applications where high specific gravity is required.

- High hardness: Tungsten alloy has high hardness and excellent wear resistance, and can maintain stable performance under high temperatures and complex environments.

- Good electrical conductivity: Tungsten alloy has good electrical conductivity and can be used to manufacture electronic components such as electrodes and contacts.

- Corrosion resistance: Tungsten alloy has good corrosion resistance in harsh environments such as acid and alkali, and can be used to manufacture chemical equipment, oil drill bits and other corrosion-resistant parts.

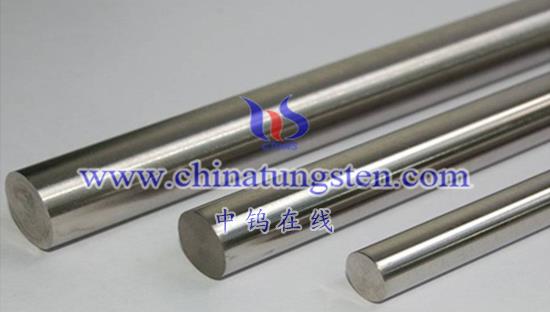

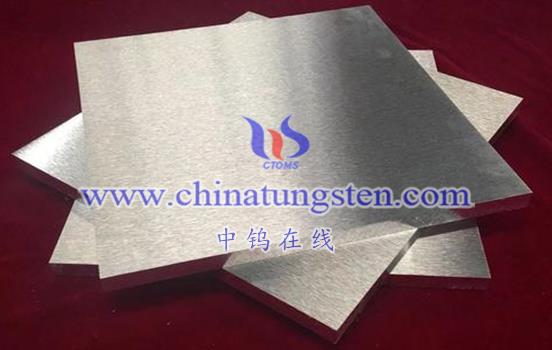

- Good processing performance: Tungsten alloy has good processing performance and can be made into products of various complex shapes through cutting, milling and other processing methods.

- Advantages and Disadvantages of Tungsten Alloy

The advantages of tungsten alloy mainly include the following points:

- High density: The density of tungsten alloy is extremely high, which can reach about 17.4g/cm³, which is much higher than other common metal materials. This characteristic makes tungsten alloys of great application value in applications where high specific gravity materials are required.

- High melting point: The melting point of tungsten alloy is very high, which can reach about 3422°C, so it can maintain stable performance in high temperature environments and has good heat resistance.

- High strength and hardness: Tungsten alloy has high hardness and tensile strength and can be used to manufacture products that need to withstand high stress, such as military equipment, aerospace vehicles, etc.

- Good electrical and thermal conductivity: Tungsten alloy has good electrical and thermal conductivity and can be used to manufacture products such as electronic components and radiators.

- Good corrosion resistance and weather resistance: Tungsten alloy has good corrosion resistance and weather resistance and can be used for a long time in various complex environments.

However, tungsten alloys also have some disadvantages:

- Limited resources: Tungsten is a rare metal with limited resources and high price. This limits the large-scale application of tungsten alloys.

- Difficulty in processing: Tungsten alloy is difficult to process and requires high-precision equipment and processes. This increases the production cost and use difficulty of tungsten alloy.

- High brittleness: Tungsten alloy is relatively brittle and prone to fracture. This limits the application of tungsten alloys in some situations that need to withstand shock and vibration.

- Environmental impact: The production and use of tungsten alloy may have certain impact on the environment. This requires strengthening environmental protection measures and reducing environmental pollution.

Tungsten alloy has both advantages and disadvantages. When applying tungsten alloy, it is necessary to comprehensively consider the actual needs and conditions and select appropriate materials and processes to achieve the best use effect.

- Application fields of tungsten alloy

- Military field: Due to the high density and hardness of tungsten alloy, it is widely used in the military field, such as manufacturing high-performance ammunition such as armor-piercing bullets and armor-breaking bullets. These munitions have extremely high penetrating power and destructive power in warfare.

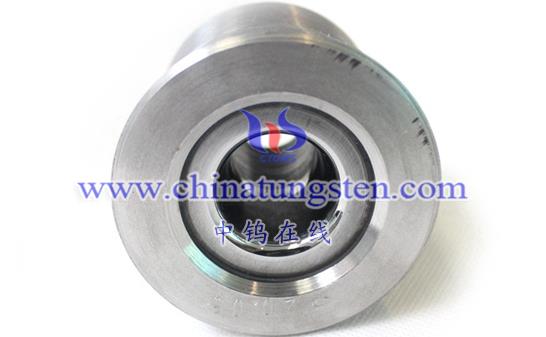

- Aerospace field: In the aerospace field, because aircraft need to withstand extremely high speeds and temperatures, high-performance materials need to be used. Tungsten alloy is widely used in the manufacturing of key components such as turbine blades and nozzles of aeroengines due to its excellent high temperature performance and corrosion resistance.

- Nuclear industry: In the nuclear industry, since neutron irradiation of metal will cause the performance of the metal to deteriorate, it is necessary to select materials with good neutron irradiation resistance. Tungsten alloy is one of the materials with relatively stable performance under neutron irradiation, so it is used to manufacture key components such as control rods and reflectors in nuclear reactors.

- Medical device field: In the medical device field, because medical devices need to have good biocompatibility and corrosion resistance, they need to use high-performance materials. Tungsten alloy is used to manufacture key components such as radiotherapy equipment and accessories for medical imaging equipment due to its good biocompatibility and corrosion resistance.

- Civilian field: In addition to the above special application fields, tungsten alloy is also widely used in civilian fields. For example, it is used to make golf heads, fishing sinkers and other sporting goods; used to make mobile phone vibrators, electronic packaging and other electronic products; used to make oil drilling bits, chemical equipment and other industrial supplies.

- Main application scenarios of tungsten alloy

Tungsten alloys are widely used in many fields due to their unique physical and chemical properties. The following are the main application scenarios of tungsten alloy:

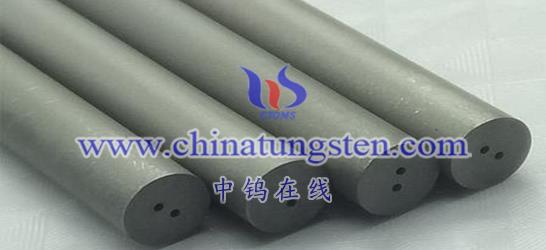

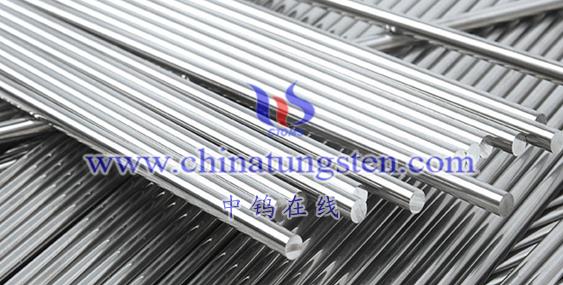

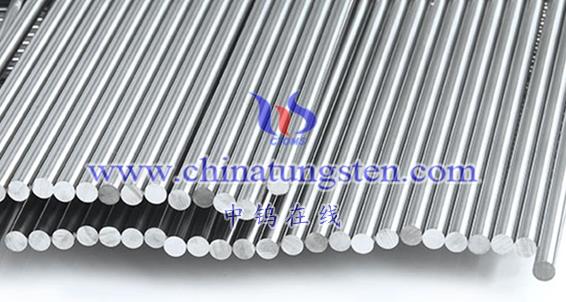

- Mechanical processing field: Tungsten alloy has high hardness, high strength and good wear resistance, so it is widely used in the field of mechanical processing. It is used to manufacture high-speed drill bits, cutting tools, wire drawing dies, etc. Tungsten alloy cutting tools can cut high-hardness metal materials, such as titanium alloys, aluminum alloys, copper, iron, etc., and have the advantages of fast cutting speed, high processing efficiency, and long service life.

- Aerospace field: Tungsten alloy is also widely used in the aerospace field, such as the production of high-temperature and high-pressure turbine blades, jet engine nozzles, rocket engine nozzles, etc. Tungsten alloy can maintain its shape and performance in harsh environments such as high temperature and high pressure. It has good corrosion resistance, heat resistance and oxidation resistance. It is one of the irreplaceable materials in the aerospace field.

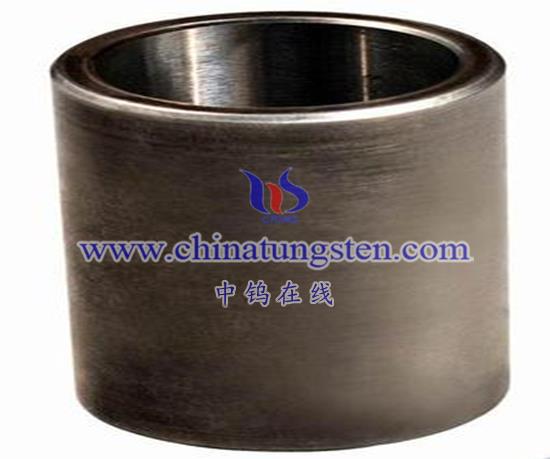

- Electronics and electric light source industry: Tungsten alloy is widely used in the electronics and electric light source industry. It is also used in aerospace, casting, weapons and other departments to make rocket nozzles, die-casting molds, armor-piercing cores, contacts, heating elements and heat insulation. Screen etc.

In addition, tungsten alloys can also be used to manufacture sporting goods such as golf heads and fishing sinkers, as well as electronic products such as mobile phone vibrators and electronic packaging. It also has potential application prospects in oil drilling, nuclear fusion reactors and other fields.

In general, with the continuous advancement of science and technology and the expansion of application fields, the application prospects of tungsten alloy will be broader.

- Development trends and prospects of tungsten alloys

With the continuous advancement of science and technology and the increasing demand for applications, the research and application of tungsten alloys will continue to deepen and expand. In the future, the development of tungsten alloys will proceed in the following directions: first, develop new high-performance tungsten alloy materials to meet a wider range of needs; second, optimize the preparation process, reduce production costs and improve product quality; third, strengthen Research on environmental protection and reduce the use of harmful elements; fourth, expand application fields and open up new market space.

The development trends and prospects of tungsten alloys can be analyzed from the following aspects:

Technological progress promotes the development of tungsten alloys

With the continuous advancement of science and technology, remarkable results have been achieved in the preparation process and performance optimization of tungsten alloys. The development of powder metallurgy technology has promoted the improvement of tungsten alloy quality and output, and also provided a technical foundation for the wide application of tungsten alloy. In the future, with further optimization and innovation of the preparation process, the performance of tungsten alloy will be further improved and its application fields will be wider.

Application areas continue to expand

Tungsten alloy has been widely used in military, aerospace, nuclear industry, medical equipment and other fields due to its excellent physical and chemical properties. With the advancement of science and technology and the increase in application requirements, the application fields of tungsten alloys will continue to expand. For example, in fields such as new energy vehicles and high-end equipment manufacturing, tungsten alloys have huge application potential. In addition, with the improvement of environmental protection requirements, the application of tungsten alloy in the field of environmental protection will gradually increase.

Market demand drives the development of tungsten alloys

With the recovery of the global economy and the rise of emerging markets, the market demand for tungsten alloys will continue to grow. Especially in Asia, with the rapid economic development and acceleration of industrialization, the demand for tungsten alloys will continue to increase. In addition, as global environmental awareness increases, the demand for environmentally friendly tungsten alloys will gradually increase.

Challenges and opportunities coexist

Although the development prospects of tungsten alloy are broad, it also faces some challenges. For example, the scarcity of tungsten resources, increased environmental protection requirements, and intensified competition in the international market have put certain pressure on the development of tungsten alloys. However, with the continuous advancement of technology and the expansion of application fields, the development of tungsten alloys will also usher in more opportunities. For example, the development of new high-performance tungsten alloy materials, optimization of preparation processes, and strengthening of international cooperation will bring new impetus to the development of tungsten alloys.

To sum up, the development trends and prospects of tungsten alloys are broad, but they also face some challenges. In future development, it is necessary to further strengthen technological innovation and application expansion, improve resource utilization efficiency, strengthen international cooperation and exchanges, and jointly promote the sustainable development of the tungsten alloy industry.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595