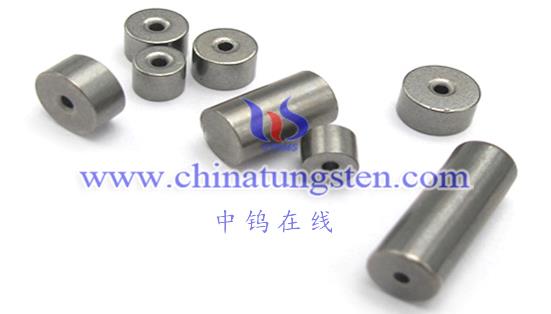

High-density tungsten alloy is a high-density alloy material with the characteristics of high strength, high specific gravity, high temperature resistance, corrosion resistance, and low expansion coefficient. In the oil and gas industry, high-density tungsten alloys can be used to manufacture a variety of heavy equipment and tools, such as drill collars, drill pipes, Christmas trees, wellhead devices, etc.

Here are some specific applications of high-density tungsten alloys in the oil and gas industry:

- Drill collars: High-density tungsten alloy has high strength and high specific gravity and can be used to make drill collars. This alloy drill collar can improve drilling efficiency, reduce wear and fatigue damage, and extend the service life of drilling tools.

- Drill pipe: High-density tungsten alloy has excellent corrosion resistance and wear resistance and can be used to make drill pipes. This alloy drill pipe can improve the wear resistance and corrosion resistance of the drill bit, reduce drill bit wear and replacement times, and reduce drilling costs.

- Christmas tree: High-density tungsten alloy has high strength and low expansion coefficient and can be used to make Christmas trees. This alloy Christmas tree can improve the stability and reliability of equipment and reduce damage and leakage caused by expansion coefficient mismatch.

- Wellhead devices: High-density tungsten alloy can be used to manufacture wellhead devices, such as wellhead flanges, valves, etc. This alloy wellhead device can improve the corrosion resistance and wear resistance of the equipment and extend the service life of the equipment.

In summary, high-density tungsten alloys play an important role in the oil and gas industry, improving equipment performance and service life, reducing maintenance costs and safety risks.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595