Tungsten mud is a muddy substance made of tungsten powder and binder, which has good adhesion and plasticity. Tungsten mud is mainly used to make tungsten products, such as tungsten crucibles, tungsten electrodes, etc. It can also be used as filler for metal smelting and welding. The following is a detailed introduction to tungsten clay:

- Manufacturing materials of tungsten clay

Tungsten mud is mainly made of tungsten powder and binder. Tungsten powder is a powdery substance of tungsten. It has the characteristics of high melting point, high density, and low thermal expansion coefficient. It is the main raw material for manufacturing tungsten products. Binder is a substance used to bind tungsten powder together, usually an organic polymer material, such as phenolic resin, epoxy resin, etc.

- Performance characteristics of tungsten mud

- Adhesion and plasticity: Tungsten clay has strong adhesion and plasticity. It can adhere to the surface of various materials and be shaped into various shapes. This makes tungsten mud an ideal raw material for making tungsten products.

- High density and low thermal expansion coefficient: The density of tungsten mud is relatively high, generally around 15-18g/cm³, which is similar to the requirements of tungsten products. At the same time, the thermal expansion coefficient of tungsten clay is low, which is beneficial to maintaining the dimensional stability of tungsten products.

- Good mechanical properties and chemical stability: Tungsten mud has good mechanical properties and chemical stability at high temperatures and is not easy to deform, crack or be oxidized. This allows tungsten mud to maintain good performance in high temperature environments.

- Easy to process and manufacture: Tungsten mud has good processing performance and can be made into various tungsten products through pressing, molding, sintering and other processes. At the same time, tungsten mud can also be used as a filler in metal smelting and welding.

- Manufacturing method of tungsten clay

Tungsten mud is a muddy substance based on tungsten, which has good softness, adhesion and plasticity. There are many ways to make tungsten clay, the following is one of the commonly used methods:

Mix tungsten powder, tungsten carbide, cobalt powder and other raw materials according to a certain proportion, then add an appropriate amount of phenolic resin as a binder, and then add an appropriate amount of plasticizer and lubricant. After thorough mixing, the semi-finished product of tungsten mud is obtained. The semi-finished product is put into the mold and sintered at high temperature to obtain the finished product of tungsten mud.

In addition, tungsten mud can also be produced through chemical synthesis. For example, sodium tungstate and nitric acid are reacted to generate tungstic acid, which is then mixed with carbon black, clay and other materials, and the tungsten mud is obtained after grinding, kneading and other processes.

In short, the method of manufacturing tungsten slime needs to be selected based on specific application scenarios and performance requirements. The tungsten clay obtained by different manufacturing methods will have different composition, performance and use effect.

- What types of tungsten mud are there?

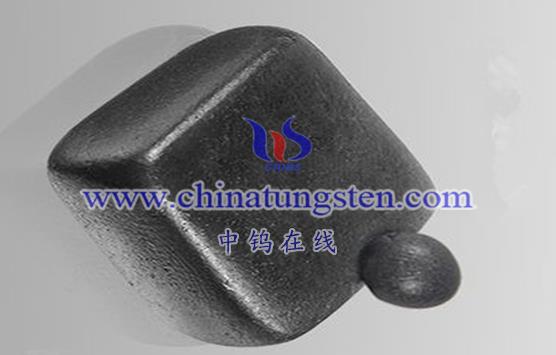

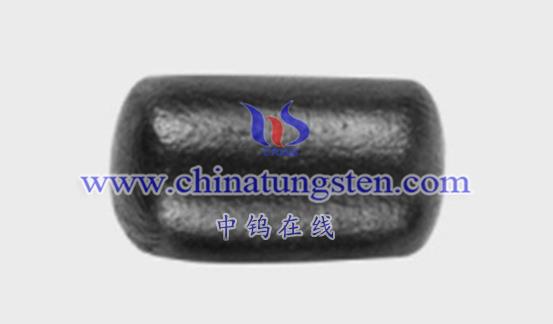

Tungsten mud is a material made of tungsten powder and high molecular polymer bonded together. It has properties such as arbitrary shape, viscosity, non-toxicity, hydrophobicity and high density. At normal temperature, tungsten clay has a fixed shape, but as the temperature rises, it gradually becomes softer and can be kneaded to change its shape like plasticine. Tungsten clay is usually gray-black, but can also be dyed into other colors.

Types of tungsten clay can be classified according to their uses and characteristics. For example, according to the use, tungsten clay can be divided into toy weight tungsten clay, fishing weight tungsten clay, etc. In addition, according to its density and viscosity characteristics, tungsten mud can also be divided into high-density tungsten mud, low-density tungsten mud, high-viscosity tungsten mud and other types.

In practical applications, it is very important to choose the appropriate tungsten mud type according to specific needs. For example, in toy manufacturing, it is necessary to choose tungsten mud with moderate density, not easy to break and non-toxic; in jewelry making, it is necessary to choose tungsten mud with high density, high hardness and beautiful color.

Tungsten clay is a material with a wide range of applications. There are many types and can be selected according to specific needs.

- Advantages of tungsten clay

Tungsten mud is a muddy substance based on tungsten, which has many advantages, including:

- High specific gravity: The specific gravity of tungsten mud is very high, which can reach 15-18g/cm³. The specific gravity is greater than that of most metals, so it has good load-bearing capacity and counterweight effect.

- Excellent wear resistance: Tungsten mud has high hardness and good friction and wear resistance, and can be used in high load and high friction environments.

- Good plasticity and adhesion: Tungsten clay has good plasticity and adhesion, can be processed and shaped into any shape as needed, and can adhere to various substrates.

- High temperature resistance and corrosion resistance: Tungsten mud can be used in high temperature and corrosive environments, is not easy to oxidize and corrode, and has stable performance.

- Non-toxic and environmentally friendly: Tungsten mud does not contain substances harmful to the human body and the environment, and is safe and environmentally friendly.

Tungsten mud has the advantages of high specific gravity, wear resistance, good plasticity, strong adhesion, high temperature resistance and corrosion resistance, and can be widely used in counterweights, filling, friction materials and other fields.

- Application fields of tungsten mud

- Tungsten product manufacturing: Tungsten mud is mainly used to manufacture tungsten products, such as tungsten crucibles, tungsten electrodes, etc. Because tungsten clay has good adhesion and plasticity, tungsten products can be produced in various shapes and sizes to meet the needs of different fields.

- Metal smelting and welding: Tungsten mud can also be used as a filler for metal smelting and welding. Because tungsten mud has the characteristics of high melting point and low thermal expansion coefficient, it is not easy to deform or crack at high temperatures, which can ensure the quality and stability of metal smelting and welding.

- Other fields: In addition to its application in tungsten product manufacturing and metal smelting and welding, tungsten clay can also be used in other fields, such as the manufacturing and processing of ceramics, glass, electronics and other industries.

Generally speaking, tungsten mud is a muddy substance made of tungsten powder and a binder, which has good adhesion and plasticity. It is widely used in tungsten product manufacturing, metal smelting and welding and other fields, and can also be used in the manufacturing and processing of other industries. With the continuous development of science and technology and the application of new technologies, the application prospects of tungsten clay will be broader. Here are some of the main applications of tungsten slime:

- Toy counterweight: Because tungsten clay has high density and plasticity, it is often used as toy counterweight, such as pine toy cars, model airplanes, etc. By kneading tungsten mud, the weight can be fine-tuned to facilitate control of the weight of the counterweight.

- Fishing sinker: The hydrophobicity and high density of tungsten mud make it an ideal material in fishing gear and can be used as a fishing sinker. It can be fixed on the fishing line or hook by gently rubbing it, and has good concealment and is easy to use in various waters.

- Other fields: In addition to the above applications, tungsten clay can also be used in jewelry making, sculpture, spacecraft counterweight, automobile manufacturing, art production and other fields.

Tungsten clay has a wide range of applications, and its unique physical properties make it uniquely useful in various fields.

- Prospects of tungsten clay

As an emerging material, the prospects of tungsten clay mainly depend on market demand and technological innovation.

From the perspective of market demand, the application fields of tungsten mud are constantly expanding. With people’s in-depth understanding of the properties of tungsten clay, its applications in jewelry, art, aerospace, automobiles and other fields are gradually increasing. At the same time, with the increasing awareness of environmental protection, tungsten clay, as a non-toxic and environmentally friendly material, is increasingly used in toys, fishing gear and other fields. Therefore, as the tungsten mud market continues to expand, the prospects for tungsten mud are promising.

From the perspective of technological innovation, there is still a lot of room for improvement in the performance of tungsten clay. At present, the strength and durability of tungsten mud need to be improved. At the same time, the manufacturing process of tungsten mud also needs to be continuously improved and perfected. If breakthroughs can be made in these aspects, the performance of tungsten mud will be greatly improved and its application areas will be further expanded.

In summary, tungsten clay, as a material with a wide range of applications, has broad prospects. With the continuous promotion of market demand and technological innovation, the application fields of tungsten clay will be further expanded, and the market prospects will be even brighter.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595