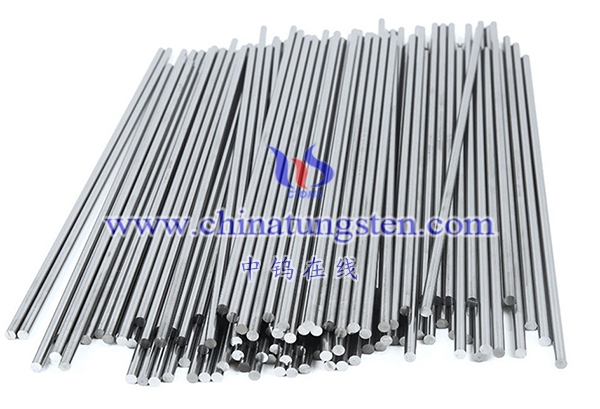

Utilizing tungsten wire for probess offer several advantages in semiconductor device production, making them a common tool in wafer testing. Here are some possible advantages:

1. High electrical conductivity: Tungsten has good electrical conductivity, which helps ensure that current can flow through the probe and achieve a reliable electrical connection. This is important for making accurate electrical measurements and testing chip performance.

2. High melting point: Tungsten has a very high melting point, which allows the utilizing tungsten wire for probes to operate stably in high temperature environments and adapt to various testing conditions.

3. High hardness: Tungsten is a material with high hardness, which helps the probe maintain a relatively stable shape during testing, reducing wear and tear, thereby extending its life.

4. Tiny size: Wafer test tungsten probes are usually designed in tiny sizes to accommodate tiny circuit components on tiny wafers. This design enables them to perform precise testing on high-density integrated circuits.

5. Wear resistance: Since wafer testing is a highly repetitive process, test tungsten probes need to have high wear resistance to ensure their long life and the ability to maintain consistency across multiple test cycles.

6. High temperature stability: Tungsten remains stable at high temperatures, allowing utilizing tungsten wire for probess to maintain performance under various testing conditions.

7. Adapt to a variety of testing environments: Due to the properties of tungsten, utilizing tungsten wire for probess are suitable for a variety of testing environments, including high temperature, high pressure, etc.

More details of tungsten needles, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595