Resistance spot welding tungsten electrode is an electrode used for resistance spot welding, usually made of tungsten or tungsten alloy. Resistance spot welding is a metal joining technology that applies high current and pressure to two metal surfaces, causing the two metal surfaces to quickly heat to the melting point and form a weld.

Here are some features and applications of tungsten electrodes for resistance spot welding:

1. High melting point: Tungsten has a very high melting point, which allows it to withstand high temperatures during resistance spot welding.

2. Electrical conductivity: Tungsten is a good conductive material, which is crucial for conducting current to the solder joint area in resistance spot welding.

3. Hardness: Tungsten has high hardness, which helps maintain the shape of the electrode and reduce wear during use.

4. Corrosion Resistance: Since resistance spot welding involves passing an electric current through an electrode, corrosion resistance is critical to the life of the electrode.

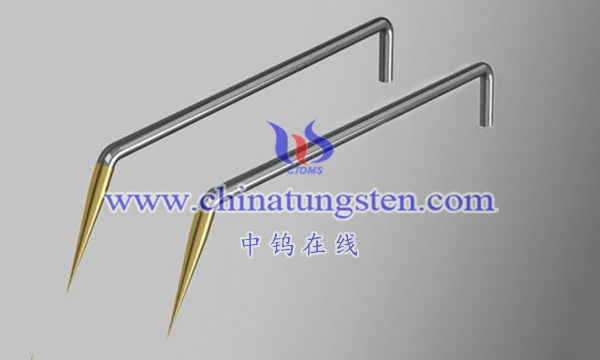

5. Sharpness: The sharpness of the resistance spot welding tungsten electrode is important for achieving precise positioning and rapid heating of the solder joint.

Resistance spot welding is widely used in the manufacturing industry, especially in the joining of metal sheets, wires or parts. As a key component in the welding process, resistance spot welding tungsten electrodes need to meet the requirements of high temperature, high current and high voltage to ensure a stable and efficient welding process.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595