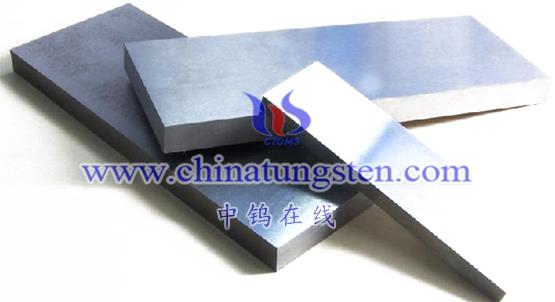

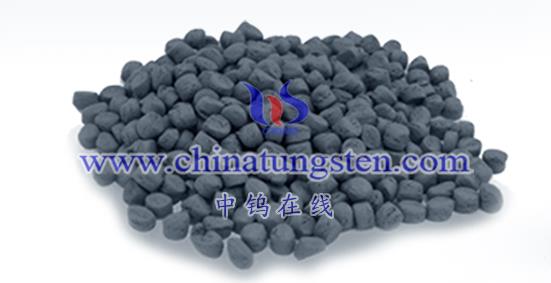

Resin tungsten polymer products are a composite material made of tungsten powder and resin materials through a special process. This material combines the excellent properties of tungsten such as high density, high hardness, high melting point, high strength and fatigue resistance with the excellent processability, insulation, corrosion resistance and light weight of resin. Resin tungsten polymer products have excellent mechanical properties, heat resistance, corrosion resistance and processing properties, so they have been widely used in aerospace, national defense and military, electronic communications, petrochemical industry, transportation, medical equipment and other fields.

- Manufacturing process of resin tungsten polymer products

The manufacturing process of resin tungsten polymer products mainly includes the following steps:

- Ingredients and mixing: Mix tungsten powder, resin and other additives according to a certain proportion and stir evenly.

- Hot press molding: Put the mixed materials into a hot press molding machine and heat press them at a certain temperature and pressure.

- Cooling and solidification: Cool and solidify the hot-pressed products to make the material more stable.

- Post-processing: Surface treatment, cutting, grinding, drilling and other processing are performed on the products to meet the needs of different fields.

- Performance and application of resin tungsten polymer products

- High density: Tungsten powder has a high density and can maintain a high density after being combined with resin. Therefore, resin tungsten polymer products can be used as high-density counterweights, supports, structural parts, etc.

- Excellent mechanical properties: Resin tungsten polymer products have excellent mechanical properties, such as high strength, high rigidity and good impact resistance, and can be used to manufacture stressed parts and structural parts.

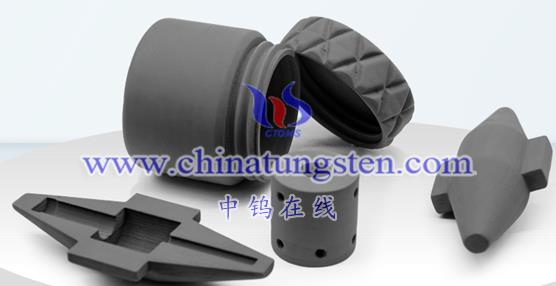

- Good processing performance: Resin tungsten polymer products can be processed using conventional mechanical processing methods, such as turning, milling, drilling, etc., with convenient processing and high precision.

- Good insulation: Resin tungsten polymer products have good insulation properties and can be used to manufacture electronic components and circuit boards.

- Corrosion resistance: Resin tungsten polymer products have excellent corrosion resistance and can be used in parts working in harsh environments, such as chemical equipment, marine engineering equipment, etc.

- Non-toxic: Resin tungsten polymer products are non-toxic, environmentally friendly and harmless to the human body. They can be used to manufacture components in food machinery, medical equipment and other fields.

- High temperature resistance: Resin tungsten polymer products have good high temperature resistance and can work at a certain temperature. They are suitable for components in high temperature environments, such as high temperature resistant components in the aerospace field.

- Excellent radiation resistance: Tungsten element has good radiation resistance, so resin tungsten polymer products also have good radiation resistance and can be used in parts in the nuclear industry and radioactive environments.

- Good hydrophobicity: Resin tungsten polymer products have good hydrophobicity and are not easy to absorb water. They are suitable for parts that need to be waterproof or moisture-proof.

- Strong plasticity: Resin tungsten polymer products have good plasticity and can be manufactured into products of various shapes and sizes through technologies such as thermoplastic molding or 3D printing.

- Advantages of resin tungsten polymer products

Resin tungsten polymer products are a composite material made of tungsten powder and resin materials, which have many advantages and disadvantages.

advantage:

- High density: Tungsten powder has a high density and can maintain a high density after being combined with resin. Therefore, resin tungsten polymer products can be used as high-density counterweights, supports, structural parts, etc.

- Excellent mechanical properties: Resin tungsten polymer products have excellent mechanical properties, such as high strength, high rigidity and good impact resistance, and can be used to manufacture stressed parts and structural parts.

- Good processing performance: Resin tungsten polymer products can be processed using conventional mechanical processing methods, such as turning, milling, drilling, etc., with convenient processing and high precision.

- Good insulation: Resin tungsten polymer products have good insulation properties and can be used to manufacture electronic components and circuit boards.

- Corrosion resistance: Resin tungsten polymer products have excellent corrosion resistance and can be used in parts working in harsh environments, such as chemical equipment, marine engineering equipment, etc.

- Non-toxic: Resin tungsten polymer products are non-toxic, environmentally friendly and harmless to the human body. They can be used to manufacture components in food machinery, medical equipment and other fields.

- High temperature resistance: Resin tungsten polymer products have good high temperature resistance and can work at a certain temperature. They are suitable for components in high temperature environments, such as high temperature resistant components in the aerospace field.

- Excellent radiation resistance: Tungsten element has good radiation resistance, so resin tungsten polymer products also have good radiation resistance and can be used in parts in the nuclear industry and radioactive environments.

- Good hydrophobicity: Resin tungsten polymer products have good hydrophobicity and are not easy to absorb water. They are suitable for parts that need to be waterproof or moisture-proof.

- Strong plasticity: Resin tungsten polymer products have good plasticity and can be manufactured into products of various shapes and sizes through technologies such as thermoplastic molding or 3D printing.

- Disadvantages of resin tungsten polymer products

- High cost: The manufacturing of resin tungsten polymer products requires the use of high-purity tungsten powder and high-quality resin, so the cost is high.

- Sensitive to temperature: Resin tungsten polymer products are easily deformed or decomposed at high temperatures, affecting their performance and service life.

- Susceptible to environmental influences: Resin tungsten polymer products are susceptible to environmental influences, such as humidity, ultraviolet rays, etc., resulting in a decrease in their performance.

- Not easy to recycle: Resin tungsten polymer products are not easy to recycle, which is not conducive to environmental protection and sustainable development.

- High processing difficulty: Although resin tungsten polymer products can be processed using conventional mechanical processing methods, their processing is difficult and requires high processing technology and precision.

In summary, resin tungsten polymer products have many advantages and disadvantages and need to be selected and used according to specific application scenarios and needs.

- Development Trend of Resin Tungsten Polymer Products

With the continuous advancement of science and technology and the expansion of application fields, the development trends of resin tungsten polymer products mainly include the following aspects:

- Research and development of new materials: Continuously explore new tungsten powder and resin materials to improve the performance and application scope of resin tungsten polymer products.

- Improvement of production process: Continuously improve and perfect the production process of resin tungsten polymer products to improve production efficiency and product quality.

- Environmental protection and sustainable development: Strengthen environmental awareness, promote environmentally friendly production processes and green materials, and promote sustainable development.

- Application of new technologies: Combine new technologies with the manufacturing of resin tungsten polymer products, such as 3D printing technology, precision processing technology, etc., to improve the accuracy and manufacturing efficiency of the products.

- Application expansion in multiple fields: Further expand the application scope of resin tungsten polymer products in aerospace, national defense and military, electronic communications, petrochemical industry, transportation, medical equipment and other fields.

In summary, resin tungsten polymer products are an important composite material with broad application prospects and continuous development potential. With the continuous advancement of science and technology and the expansion of application fields, it is believed that resin tungsten polymer products will play an important role in more fields.

More details of polymer tungsten product, please visit website: Polymer Tungsten – Polymer Tungsten Products Manufacturer and Supplier (poly-tungsten.com)

Please contact CHINATUNGSTEN for inquiry and order of tungsten polymer:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595