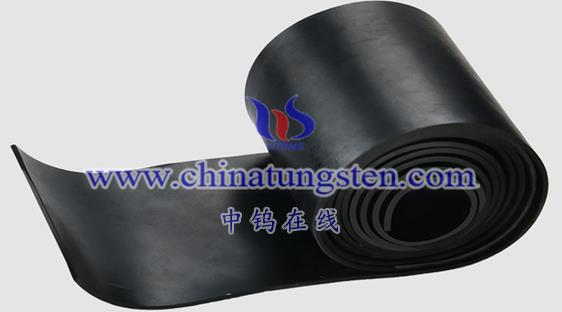

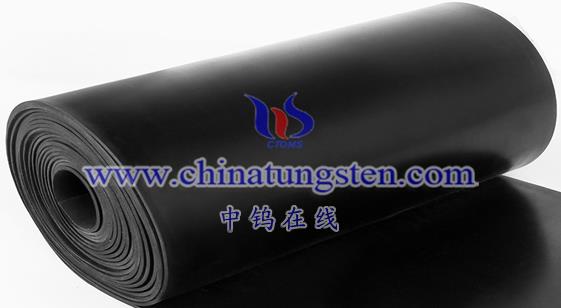

Tungsten resin is a material composed of tungsten powder and thermosetting resin. It has the characteristics of high strength, high hardness, high temperature resistance and corrosion resistance. Tungsten resin can be processed into products of various shapes and sizes and is widely used in aerospace, energy, chemical industry and other fields. The following is a detailed introduction to tungsten resin:

- Tungsten resin manufacturing materials

Tungsten resin is composed of tungsten powder and thermosetting resin. Tungsten powder is a high-purity tungsten powder prepared by methods such as chemical vapor deposition or powder metallurgy. It has the characteristics of high density, high hardness, and high melting point. Thermosetting resin is a resin that can undergo a curing reaction under the action of heating or cross-linking agents. It has excellent mechanical properties and corrosion resistance. Commonly used thermosetting resins include epoxy resin, phenolic resin, etc.

- Performance characteristics of tungsten resin

- High strength and high hardness: Tungsten resin has high strength and hardness, its tensile strength can reach more than 1000MPa, and Vickers hardness can reach about 1500HV. This is mainly due to the high strength and high hardness of tungsten powder.

- High temperature resistance: Tungsten resin has good high temperature resistance, can be used at higher temperatures for a long time, and is not easy to deform or crack.

- Corrosion resistance: Tungsten resin has good corrosion resistance and can withstand the corrosion of various acids, alkalis, salts and other chemical reagents. It is suitable for chemical industry, energy and other fields.

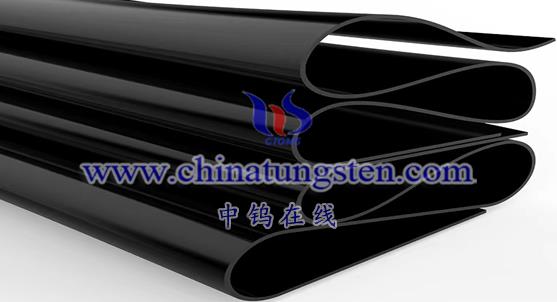

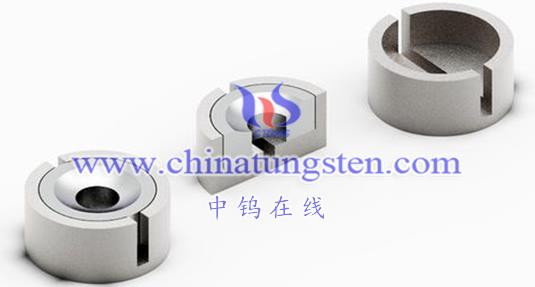

- Strong processability: Tungsten resin can be processed into products of various shapes and sizes through injection molding, hot press molding, injection molding, etc., which is convenient and fast.

- Environmentally friendly and sustainable: The tungsten powder used in tungsten resin can be recycled and reused, which meets the requirements of environmental protection and sustainability.

- Application fields of tungsten resin

- Aerospace field: Tungsten resin can be used to manufacture aircraft parts, rocket engine parts, etc. It has the characteristics of high strength and high temperature resistance.

- Energy field: Tungsten resin can be used to manufacture solar panel frames, wind power equipment components, etc. It has the characteristics of corrosion resistance and high strength.

- Chemical industry: Tungsten resin can be used to manufacture chemical equipment parts such as pipes, valves, reactors, etc. It has the characteristics of corrosion resistance and high strength.

- Other fields: Tungsten resin can also be used in automobile parts manufacturing, medical device manufacturing and other fields, and has the characteristics of high strength and high hardness.

Generally speaking, tungsten resin is a composite material made of tungsten powder and thermosetting resin. It has the characteristics of high strength, high hardness, high temperature resistance, corrosion resistance and other characteristics. It is widely used in aerospace, energy, chemical industry and other fields, providing new solutions and material options for manufacturing and processing in various industries. With the continuous development of science and technology and the application of new technologies, the application prospects of tungsten resin will be broader.

More details of polymer tungsten product, please visit website: Polymer Tungsten – Polymer Tungsten Products Manufacturer and Supplier (poly-tungsten.com)

Please contact CHINATUNGSTEN for inquiry and order of tungsten polymer:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595