High-density tungsten alloy has good performance in nuclear reactor fuel cladding. Nuclear reactor fuel cladding needs to withstand extreme environments such as high temperature, high pressure and strong radiation, so it requires materials with good heat resistance, corrosion resistance and high strength.

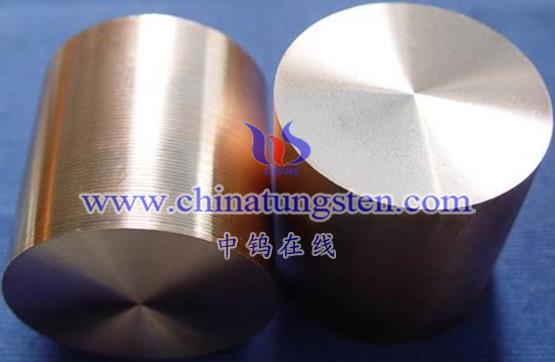

High-density tungsten alloy has the characteristics of high melting point, high density and excellent heat resistance. It can effectively absorb and reduce the spread of radiation and reduce the impact of radiation on the interior of the facility and the surrounding environment. In addition, tungsten alloy also has good corrosion resistance and high strength, and can maintain stable performance in corrosive environments such as strong acid and strong alkali.

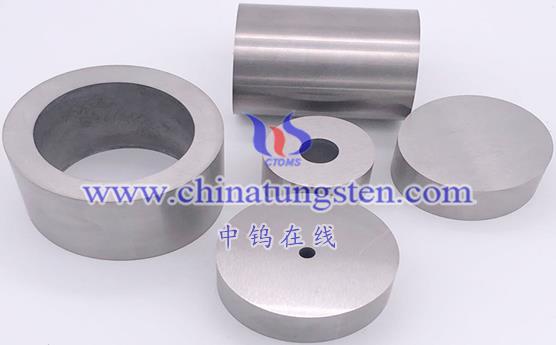

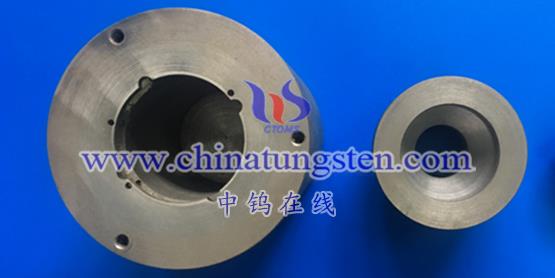

In nuclear reactor fuel cladding, tungsten alloy is usually made into the form of thin-walled tubes or thick-walled tubes for wrapping nuclear fuel pellets. The thickness of the tungsten alloy tube wall is determined according to specific needs, and high-precision and high-finish processing can be achieved on thinner tube walls to ensure the sealing and reliability of the fuel cladding.

In general, high-density tungsten alloys have good performance in nuclear reactor fuel cladding and can meet the extreme environmental and safety requirements of nuclear reactors. With the continuous development and advancement of nuclear energy technology, high-density tungsten alloys will still play an important role in future nuclear reactors and other nuclear facilities.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595