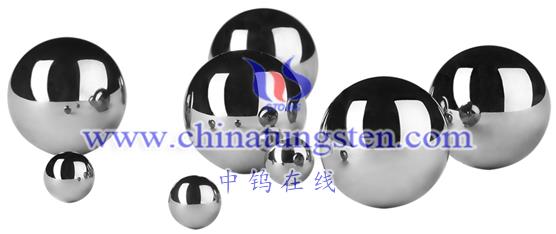

Tungsten alloy ball is a spherical product made of tungsten alloy material, which has the characteristics of high density, high strength, high temperature resistance and corrosion resistance. Tungsten alloy balls are widely used in energy, chemical industry, aerospace, military and other fields, and are mainly used as counterweights, supports, shielding parts, etc.

- Manufacturing of tungsten alloy balls

The manufacturing process of tungsten alloy balls mainly includes raw material preparation, mixing, pressing, sintering and post-processing.

- Preparation of raw materials: The raw materials of tungsten alloy balls include tungsten powder, rhenium powder, copper powder and other metal powders. These powders require careful preparation and processing to ensure the uniformity and stability of their composition and organizational structure.

- Mixing: Mixing the prepared metal powders such as tungsten powder, rhenium powder and copper powder evenly according to a certain proportion is an important step in manufacturing tungsten alloy balls. During the mixing process, the particle size and distribution of the powder need to be strictly controlled to ensure the uniformity and stability of the mixing.

- Press molding: Put the mixed tungsten alloy powder into a mold for press molding to form a green body with a certain shape and size. The pressure and temperature need to be controlled during the pressing process to ensure the density of the green body and the stability of the tissue structure.

- Sintering: The pressed green body is sintered at high temperature to melt and solidify the tungsten alloy powder at high temperature. The temperature and time need to be controlled during the sintering process to ensure the stability of the grain structure and mechanical properties of the tungsten alloy balls.

- Post-processing: The sintered tungsten alloy balls need to be post-processed, including heat treatment, surface treatment and processing. Heat treatment can eliminate internal stress and improve the hardness and wear resistance of tungsten alloy balls; surface treatment can enhance the corrosion resistance and aesthetics of tungsten alloy balls; the processing link can carry out finishing and surface treatment on tungsten alloy balls to meet the needs of different fields needs.

- Characteristics and applications of tungsten alloy balls

- High density: The density of tungsten alloy balls is as high as 16.5-19.0g/cm³, which is much higher than ordinary steel materials. Therefore, it has excellent characteristics of light weight and small size, and is suitable for aerospace, energy and other fields.

- High strength: Tungsten alloy balls have high tensile strength and compressive strength, can withstand large pressure and tensile force, and are suitable for manufacturing counterweights, supports, etc.

- High temperature resistance: Tungsten alloy balls have good high temperature performance and can maintain stable performance in high temperature environments. They are suitable for manufacturing supports, shielding parts, etc. in high temperature environments.

- Corrosion resistance: Tungsten alloy balls have good corrosion resistance and can resist the erosion of chemicals such as acids, alkalis, and salts, and are suitable for chemical industry and other fields.

- Electromagnetic properties: Tungsten alloy balls have good electromagnetic properties and can absorb and shield electromagnetic waves. They are suitable for manufacturing electromagnetic shielding parts, electronic components, etc.

- Nuclear radiation protection: Because tungsten alloy balls have the characteristics of high density and high atomic number, they can absorb and scatter radioactive radiation and are suitable for radiation protection and shielding in the nuclear industry.

- Military applications: Due to the characteristics of high density and high strength, tungsten alloy balls are widely used in military fields, such as manufacturing armor-piercing cores, bullets and other weapon components.

- Other applications: In addition to the above application fields, tungsten alloy balls are also widely used in energy, aerospace, medical equipment and other fields, such as manufacturing counterweights for wind turbine blades, supports for aircraft landing gear, etc.

- Summary and Outlook

As a product with high density, high strength, high temperature resistance and corrosion resistance, tungsten alloy balls have broad application prospects in energy, chemical industry, aerospace, military and other fields. With the continuous advancement of science and technology and the growing demand for applications, the research and development and application of tungsten alloy balls will continue to develop and improve. In the future, it is necessary to further research new tungsten alloy materials and preparation technologies to improve the performance and application range of tungsten alloy balls to meet the needs of different fields. At the same time, with the continuous improvement of environmental awareness, it is necessary to actively explore green and environmentally friendly preparation technologies and application fields to achieve sustainable development.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595