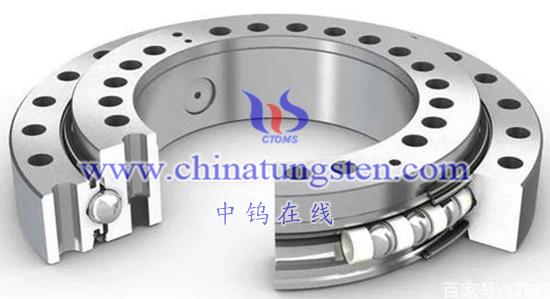

Tungsten alloy support is a mechanical support component made of tungsten alloy material. It has good mechanical properties, high temperature resistance and corrosion resistance. It is widely used in aerospace, military, petrochemical, automobile manufacturing and other fields.

- Manufacturing of tungsten alloy supports

The manufacturing process of tungsten alloy supports mainly includes raw material preparation, mixing, pressing, sintering and post-processing.

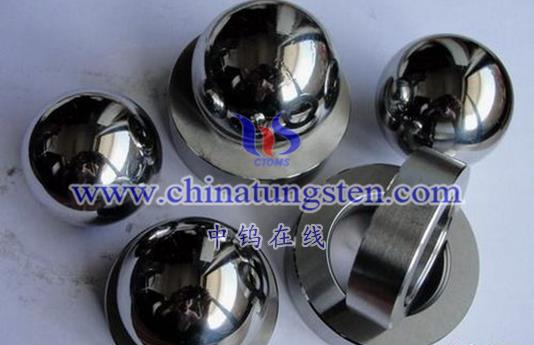

- Raw material preparation: The raw materials of tungsten alloy support parts include tungsten powder, rhenium powder, copper powder and other metal powders. These powders require careful preparation and processing to ensure the uniformity and stability of their composition and organizational structure.

- Mixing: Mixing the prepared metal powders such as tungsten powder, rhenium powder and copper powder evenly according to a certain proportion is an important step in manufacturing tungsten alloy supports. During the mixing process, the particle size and distribution of the powder need to be strictly controlled to ensure the uniformity and stability of the mixing.

- Press molding: Put the mixed tungsten alloy powder into a mold for press molding to form a green body with a certain shape and size. The pressure and temperature need to be controlled during the pressing process to ensure the density of the green body and the stability of the tissue structure.

- Sintering: The pressed green body is sintered at high temperature to melt and solidify the tungsten alloy powder at high temperature. The temperature and time need to be controlled during the sintering process to ensure the stability of the grain structure and mechanical properties of the tungsten alloy support.

- Post-processing: The sintered tungsten alloy support parts need to be post-processed, including heat treatment, surface treatment and processing. Heat treatment can eliminate internal stress and improve the hardness and wear resistance of tungsten alloy supports; surface treatment can enhance the corrosion resistance and aesthetics of tungsten alloy supports; the processing link can carry out finishing and surface treatment on tungsten alloy supports to improve Meet the needs of different fields.

- Characteristics and applications of tungsten alloy supports

- High density: Tungsten alloy materials have high density and can provide greater load-bearing capacity, so tungsten alloy supports can withstand greater loads and pressures. In application scenarios that need to withstand high loads, such as aerospace, military and other fields, tungsten alloy supports can provide stable support and fixation effects.

- High strength: Tungsten alloy material has high strength and good toughness, which makes the tungsten alloy support parts have high load-bearing capacity and impact resistance. In complex working environments, such as high-speed operation, high temperature or low temperature and other extreme conditions, tungsten alloy supports can maintain their stability and reliability.

- High temperature resistance: Tungsten alloy materials have good high temperature resistance and can maintain stable performance in high temperature environments. In high-temperature environments, such as aerospace engines, rocket thrusters and other high-temperature equipment, tungsten alloy supports can maintain their load-bearing capacity and accuracy, ensuring the normal operation of the equipment.

- Corrosion resistance: Tungsten alloy materials have good corrosion resistance and can resist the erosion of chemicals such as acids, alkalis, and salts. Under harsh environmental conditions, such as marine environment, chemical industry and other fields, tungsten alloy supports can maintain their performance and stability and extend their service life.

- Good electromagnetic properties: Tungsten alloy materials have good electromagnetic properties and can absorb and shield electromagnetic waves. In electronic equipment and electromagnetic wave sensitive equipment, tungsten alloy supports can play the role of electromagnetic shielding and improve the stability and reliability of the equipment.

- Environmentally friendly and non-toxic: Tungsten alloy support is an environmentally friendly material that does not produce toxic substances and is harmless to the environment and human health. This is in line with the requirements of modern industry for environmental performance.

- Easy to process and customize: Due to the excellent performance and stability of tungsten alloy supports, they are easy to process and customize. It can be processed and manufactured through conventional machining and casting processes, and installation is simple and quick.

- Long life: Due to the excellent performance and stability of tungsten alloy supports, they have a long service life, reduce the frequency of replacement and maintenance, and reduce operating costs.

- Wide range of applications: Tungsten alloy supports have a wide range of applications, not only for mechanical equipment and facilities in the industrial field, but also for sensitive equipment and personnel protection in aerospace, military and other fields.

- Summary and Outlook

In summary, as a mechanical support component with high density, high strength, high temperature resistance, corrosion resistance, easy processing and customization, and a wide range of applications, tungsten alloy supports have broad application prospects in many fields. With the continuous advancement of science and technology and the growing demand for applications, the research and development and application of tungsten alloy supports will continue to develop and improve. In the future, it is necessary to further research new tungsten alloy materials and preparation technologies to improve the mechanical properties, high temperature resistance, corrosion resistance and other performance indicators of tungsten alloy supports to meet the needs of different fields. At the same time, with the continuous improvement of environmental awareness, it is necessary to actively explore green and environmentally friendly preparation technologies and application fields to achieve sustainable development.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595