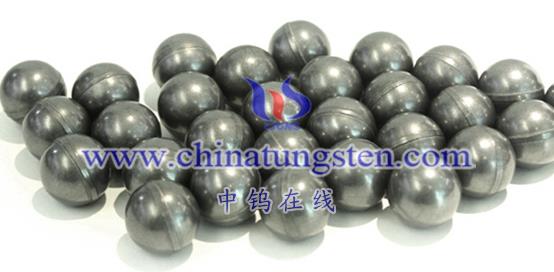

Tungsten alloy ball is a high-density metal product that is widely used in various fields due to its unique physical and mechanical properties. The following are some main application scenarios of tungsten alloy balls:

- Military defense and weapons manufacturing: Tungsten alloy balls are often used as anti-personnel components in the military field, such as the counterweight part of armor-piercing bullets and armor-piercing bullets, and the balancing component of missile warheads. Its high density and strength give it important applications in military defense and weapons manufacturing.

- Aerospace field: In the aerospace field, tungsten alloy balls can be used as manufacturing materials for high-temperature and high-pressure components such as rocket engine nozzles and turbine blades. Its excellent heat resistance, corrosion resistance and oxidation resistance make it an indispensable metal material in the aerospace industry.

- Electronic industry and semiconductor manufacturing: Because tungsten alloy balls have low thermal expansion coefficient and good electrical conductivity, they are widely used in the electronic industry and semiconductor manufacturing fields. For example, tungsten alloy balls are used in metal connecting wires in integrated circuits and electrodes in vacuum electronic devices.

- Medical field: In the medical field, tungsten alloy balls can be used to manufacture surgical knives, prosthetics, dental and orthopedic tools, etc. Because tungsten alloy balls have excellent biocompatibility and corrosion resistance, their application in the medical field can improve the reliability and safety of medical equipment.

- Sports equipment and entertainment equipment: Tungsten alloy balls can be used as counterweights for sports equipment such as skis and gliders to improve the stability and performance of sports equipment. In addition, in entertainment equipment, such as carousels, game consoles, etc., tungsten alloy balls are often used as counterweights to balance the center of gravity of the equipment.

- Precision instrument manufacturing: In precision instrument manufacturing, tungsten alloy balls are often used as balancing parts, such as clocks, precision instruments, optical instruments, etc. Due to its high precision and stability, tungsten alloy balls can improve the measurement accuracy and stability of precision instruments.

- Oil drilling and mining equipment: In oil drilling and mining equipment, tungsten alloy balls are often used as materials for drill bits, cutting tools, etc. to improve the wear resistance and service life of the tools.

- Jewelry manufacturing: Due to its high density and beautiful appearance, tungsten alloy balls are also used in the manufacture of jewelry. It can be used as a weight for pendants, earrings and other jewelry to increase the beauty and wearing comfort.

- Mechanical processing field: Tungsten alloy has high hardness, high strength and good wear resistance, and is widely used in the field of mechanical processing. It is used to manufacture high-speed drill bits, cutting tools, wire drawing dies, etc. Tungsten alloy cutting tools can cut high-hardness metal materials, such as titanium alloys, aluminum alloys, copper, iron, etc., and have the advantages of fast cutting speed, high processing efficiency, and long service life.

The following are some practical application examples of tungsten alloy balls:

- Golf ball manufacturing: Tungsten alloy balls are often used as golf ball counterweights due to their high density and stable physical properties. This helps keep the ball balanced and improves ball flight.

- Military weapons and ammunition manufacturing: In the military field, tungsten alloy balls are often used as counterweights or anti-personnel components for weapons and ammunition. For example, tungsten alloy balls can be used as the counterweight part of armor-piercing and armor-piercing projectiles to improve shooting accuracy.

- Oil drilling platform counterweight: In oil drilling platforms, tungsten alloy balls are often used as counterweights to balance the weight of the drilling rig and improve the stability and efficiency of drilling.

- Precision instrument manufacturing: When manufacturing precision instruments, such as clocks, optical instruments, etc., tungsten alloy balls are often used as balancing parts to improve the accuracy and stability of instrument measurement.

- Sports equipment manufacturing: In the manufacturing of sports equipment such as skis and gliders, tungsten alloy balls are often used as counterweights to improve the stability and performance of the equipment.

- Jewelry manufacturing: Due to its high density and beautiful appearance, tungsten alloy balls are often used to manufacture jewelry counterweights, such as pendants, earrings, etc.

- Mechanical processing field: Tungsten alloy balls are also used in the field of mechanical processing, such as as materials for cutting tools, drill bits and other tools to improve the wear resistance and service life of the tools.

- Aerospace field: In the aerospace field, tungsten alloy balls can be used as materials for high-temperature and high-pressure components such as rocket engine nozzles and turbine blades.

- Nuclear industry: Due to its high temperature resistance and corrosion resistance, tungsten alloy balls are also used in the nuclear industry, such as as control rod materials for nuclear reactors.

In summary, tungsten alloy balls have broad application prospects in various fields. With the continuous development of science and technology, the application fields of tungsten alloy balls will be further expanded, and they will continue to play an important role in future development.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595