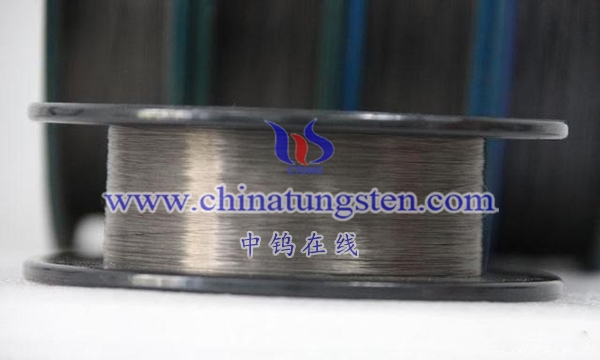

The manufacturing process of tungsten wires includes the following steps:

1. Raw material preparation: The first step in manufacturing tungsten wire is to prepare raw materials. High-purity tungsten rods or tungsten wires are usually used as raw materials.

2. Heating and shaping: The raw material is heated to a high temperature to make it sufficiently plastic, and then shaped and drawn to form a slender tungsten wire.

3. Cooling and shaping: After heating and shaping, the tungsten wire needs to be cooled and shaped to make the shape more stable and ensure that it remains unchanged at room temperature.

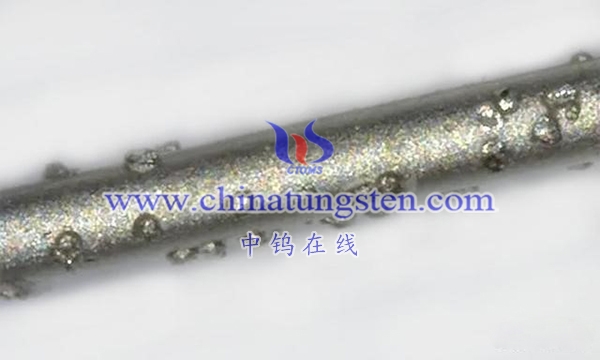

4. Grinding and polishing: After cooling and shaping, the tungsten wire needs to be ground and polished to remove defects such as burrs, uneven surfaces, and oxide layers, making the surface smoother and cleaner. At the same time, the sensitivity and accuracy of tungsten wire can also be improved.

5. Quality inspection: After the above steps, the tungsten wire needs to undergo quality inspection to ensure that it meets the requirements. Quality inspection includes dimensional inspection, appearance inspection, performance test and other aspects. Only tungsten wire that meets the requirements can be considered qualified.

6. Packaging and Shipping: The last step is to pack and ship. The purpose of packaging is to protect the tungsten wire from damage during transportation while also increasing its aesthetics. After packaging, the tungsten wire is ready to be transported to its destination.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595