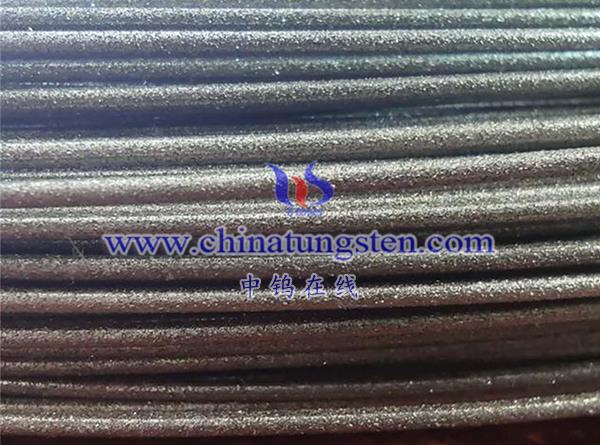

Tungsten wire for diamond wire busbar has the following advantages:

1. Smaller diameter: The diameter of tungsten wire for diamond wire busbar is smaller than traditional steel wire, which can reduce the loss rate of silicon wafers and improve cutting efficiency.

2. Lower wire breakage rate: Tungsten wire for diamond wire busbar has higher tensile strength, better toughness and fatigue resistance, so the wire breakage rate is lower, which can reduce production costs.

3. Better corrosion resistance and oxidation resistance: Tungsten wire for diamond wire busbar is not easily oxidized or corroded at high temperatures and can maintain stable performance and accuracy.

4. Efficient cutting: Tungsten wire for diamond wire busbar can cut silicon wafers faster and improve production efficiency.

5. Wide range of applications: Tungsten wire for diamond wire busbar can be applied to different types and specifications of cutting equipment and application scenarios.

6. High cost performance: Although the manufacturing cost of tungsten wire for diamond wire busbar is high, its advantages such as high performance, long life and low maintenance cost make it more cost effective.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595