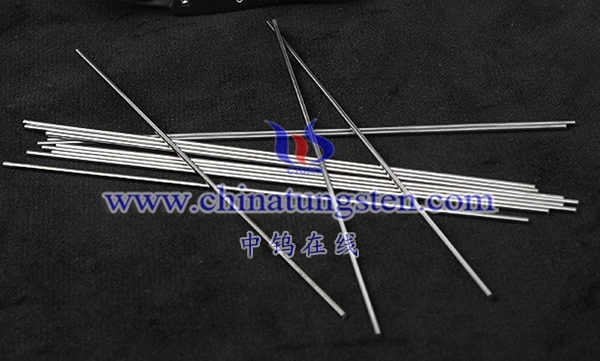

Tungsten rod is a slender metal rod made of tungsten that is commonly used to make a variety of industrial parts and tools. It has the advantages of high density, high melting point, high hardness, low conductivity and good mechanical properties, so it shows excellent performance in high temperature and high current application scenarios. Tungsten rods are usually made using powder metallurgy technology and have high density and good surface quality. It can also be used to make electrode materials, such as tungsten wires and tungsten ribbons, for use in electron-emitting devices, electric light sources, X-ray sources, etc.

The manufacturing process of tungsten rods includes a series of complex processes, including preparation of tungsten powder, pressing, sintering, processing and heat treatment. These processes require precise control of parameters such as tungsten particle size, purity, density and grain structure to ensure the high quality and performance of the tungsten rod.

Tungsten rods are widely used in industrial fields, such as manufacturing high-temperature stoves, high-temperature instruments, aerospace parts and various high-speed cutting tools, etc. In addition, tungsten rods can also be used to manufacture various medical devices, such as scalpels, surgical scissors, surgical forceps and other medical devices, as well as medical products such as artificial joints that are long-term implanted in the human body.

Tungsten rod is a metal rod material with excellent performance. It shows good performance in high temperature and high current application scenarios, and has wide application prospects in industrial and medical fields.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595