Spot welding tungsten rod is a special electrode material used in spot welding processes, usually made of tungsten. Spot welding is a welding method that fuses two metal surfaces together. By applying current and pressure to the area to be welded, the metal surfaces melt and solidify into a welding point.

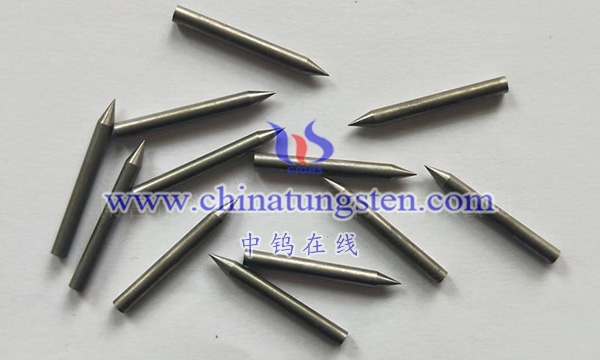

Spot welding tungsten rods have the characteristics of high melting point, high hardness, low conductivity, etc., and can maintain stability and durability at high temperatures. Its head is usually tapered or needle-shaped, allowing it to easily enter narrow welding sites and produce a high-temperature arc that fuses metal surfaces together.

The design and manufacturing process of spot welding tungsten rods is very strict and requires multiple processes and inspections to ensure that their quality and performance meet the requirements. This kind of electrode usually needs to have characteristics such as high purity, high density, high hardness, and low conductivity to ensure that it can maintain stability and accuracy in high-temperature, high-current working environments.

Spot welding tungsten rods play an important role in the spot welding process. It can provide stable arc and current, produce high-precision welding points, and reduce welding deformation and residual stress and other undesirable phenomena. At the same time, spot welding tungsten rods also have high strength and good wear resistance, which can ensure the quality and reliability of welding points.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595