The manufacturing process of tungsten needles is a complex process involving multiple steps. Here are the steps in more detail:

1. Material selection: Tungsten is a metal material with high density, high melting point, good electrical conductivity and corrosion resistance. It is widely used in manufacturing cemented carbide, tungsten wire and other high-precision components. The raw material for manufacturing tungsten needles is high-purity tungsten block.

2. Heating treatment: Put the tungsten block into the furnace for heating treatment to make it reach a certain temperature to improve its plasticity. This step is also called annealing.

3. Wire drawing treatment: Pass the heated tungsten block through a mold called a “drawing die” to draw it into a slender tungsten wire. This step is also called drawing or rolling.

4. Heat treatment again: Heat the drawn tungsten wire again to further improve its plasticity. This step is also called softening.

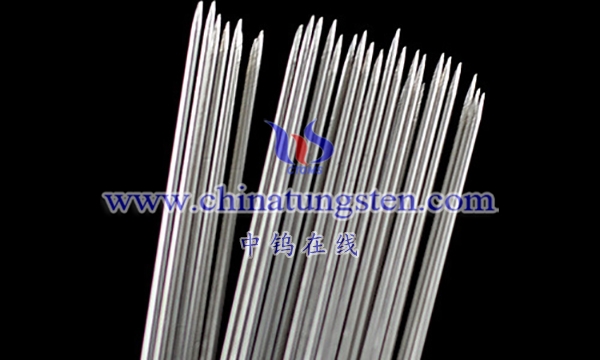

5. Further processing: The heat-treated tungsten wire is processed into a tungsten needle of the required shape through a series of tools and molds. This step may include bending, cutting, grinding, etc.

6. Polishing treatment: Use a polishing machine or other tools to polish the surface of the tungsten needle to increase its surface finish and quality. The polishing process may require the use of abrasives or other polishing materials.

7. Quality inspection: Finally, quality inspection is performed on the manufactured tungsten needle, including dimensional measurement, shape inspection, etc., to ensure that it meets the requirements. If any tungsten needles that do not meet the specifications are found, they need to be processed or reworked accordingly.

During the manufacturing process, the control of parameters such as temperature and pressure is very important. For example, the temperature and time of the heat treatment need to be precisely controlled to ensure that the lattice structure of tungsten is correctly adjusted; the pressure and speed during drawing and processing also need to be precisely controlled to avoid excessive stress and cracks. In addition, the cleanliness and humidity in the manufacturing environment also need to be strictly controlled to avoid impurities and contaminants from affecting the quality of tungsten needles.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595