The rotary forging process is a metal processing technology that repeatedly compresses and stretches the metal blank through a rotary forging machine to obtain the required shape and size. The following will introduce in detail how to produce tungsten wire using the rotary forging process.

1. Raw material preparation

The raw material for swaging tungsten wire is tungsten blank, usually tungsten rod or tungsten rod is used as the blank. In the preparation stage, the tungsten billet needs to be selected, dried and cut to ensure that its quality and size meet the requirements.

2. Heating and forging

After preparing the tungsten billet, it is placed in the heating furnace of the swaging machine for heating. Heating temperature and time need to be set according to the characteristics of tungsten and the desired shape and size. During the heating process, attention needs to be paid to controlling the heating speed and temperature to ensure that the tungsten billet is heated evenly and to avoid cracks or deformation.

After the tungsten billet is heated to a certain temperature, it is taken out and quickly placed into the die of the swaging machine. In the mold, the tungsten blank is repeatedly compressed and stretched to gradually form the desired shape and size. During the forging process, attention needs to be paid to controlling the forging speed and intensity, as well as the temperature and lubrication of the mold, to ensure that the quality and performance of the tungsten wire meet the requirements.

3. Cooling and straightening

After repeated compression and extension by the swaging machine, the shape and size of the tungsten wire have been basically formed. At this time, the tungsten wire needs to be cooled to prevent it from deforming or cracking. The cooling method can be natural cooling or forced cooling, and the specific choice needs to be determined according to the actual situation.

After the tungsten wire is completely cooled, it needs to be straightened to eliminate the bending and unevenness of the tungsten wire. Straightening treatment can be achieved through a straightening machine. By adjusting the parameters and operating methods of the straightening machine, the required straightness and surface quality can be obtained.

4. Quality inspection

After the above steps, the tungsten wire needs to be inspected for quality. The testing content includes appearance quality, dimensional accuracy, density and hardness, etc. Quality inspection is an important step to ensure that tungsten wire meets the requirements, so the quality and accuracy requirements of each link need to be strictly controlled.

5. Application

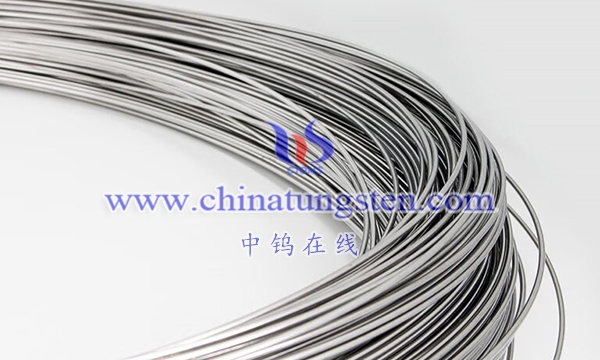

Tungsten wire produced by the rotary forging process has the advantages of high density, high strength, high corrosion resistance and good electrical conductivity, so it is widely used in many fields. In the electronics industry, swaged tungsten wire is used to manufacture heating elements and electrodes in electron tubes, transistors and other devices. In addition, swaged tungsten wire is also used to manufacture heating elements in high-temperature furnaces, additives in tool steel, etc.

In short, the production of tungsten wire using the rotary forging process requires multiple steps and complex process technology, and requires corresponding professional technology and equipment for production. At the same time, due to the rarity and high value of tungsten metal, the production cost of swaged tungsten wire is relatively high and the price is relatively expensive. However, due to its excellent performance and wide application prospects, swaged tungsten wire is still a very important material with broad market prospects and development potential.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595