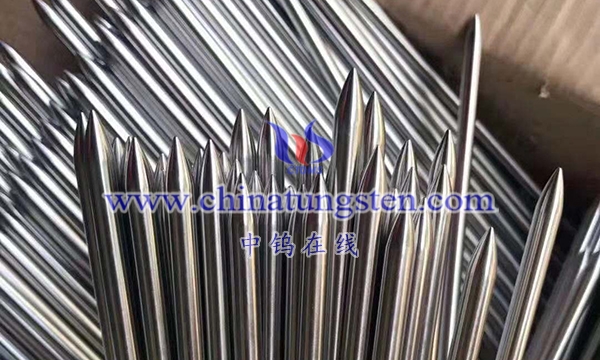

Straightened tungsten wire is a specially processed tungsten wire with the advantages of high purity, high density, high strength, high hardness, high wear resistance and good electrical conductivity. In the process of producing tungsten wire, it undergoes a series of processing and treatments, such as high-temperature smelting, forging, rotary forging, heat treatment and surface treatment, etc., and finally obtains a straight-shaped tungsten wire.

- Raw material preparation

The raw material for straightening tungsten wire is high-purity tungsten powder or tungsten strip. In the preparation stage, tungsten powder or tungsten strips need to be selected, dried and cut to ensure that their quality and size meet the requirements.

- High temperature smelting

After preparing the tungsten powder or tungsten strip, put it into a high-temperature smelting furnace for smelting. The purpose of high-temperature smelting is to remove impurities from tungsten powder or tungsten strips and melt them into liquid tungsten. During the high-temperature smelting process, attention needs to be paid to controlling the smelting temperature and time to ensure that the quality and purity of liquid tungsten meet the requirements.

- Forging and rotary forging

After being melted at high temperature, liquid tungsten is poured into the mold and subjected to forging and rotation. The purpose of forging and rotary forging is to process liquid tungsten into the desired shape and size. During the forging and rotary forging processes, attention needs to be paid to controlling the processing temperature, processing speed and processing intensity to ensure that the quality and performance of the tungsten wire meet the requirements.

- Heat treatment

After forging and rotary forging, the shape and size of the tungsten wire have been basically formed. At this time, the tungsten wire needs to be heat treated to further enhance its strength and hardness. The purpose of heat treatment is to change the internal structure of tungsten wire to make it have higher strength and hardness by controlling the heating temperature and time. During the heat treatment process, attention needs to be paid to controlling the heating temperature and time to ensure that the quality and performance of the tungsten wire meet the requirements.

- Surface treatment

After heat treatment, the tungsten wire needs to be surface treated to eliminate surface defects and improve surface quality. The purpose of surface treatment is to make the surface of tungsten wire smooth, flat and defect-free through chemical corrosion, mechanical polishing and other methods to improve its aesthetics and performance. During the surface treatment process, attention needs to be paid to controlling the treatment temperature, treatment time and treatment intensity to ensure that the quality and performance of the tungsten wire meet the requirements.

- Straightening treatment

After surface treatment, the tungsten wire needs to be straightened to eliminate its bending and unevenness. The purpose of the straightening treatment is to achieve the required straightness and surface quality of the tungsten wire through the stretching and compression effects of the straightening machine. During the straightening process, attention needs to be paid to controlling the parameters and operating methods of the straightening machine to ensure that the quality and performance of the tungsten wire meet the requirements.

- Quality inspection

After the above steps, the straightening tungsten wire needs to be inspected for quality. The testing content includes appearance quality, dimensional accuracy, density and hardness, etc. Quality inspection is an important step to ensure that the straightening tungsten wire meets the requirements, so the quality and accuracy requirements of each link need to be strictly controlled.

- Application

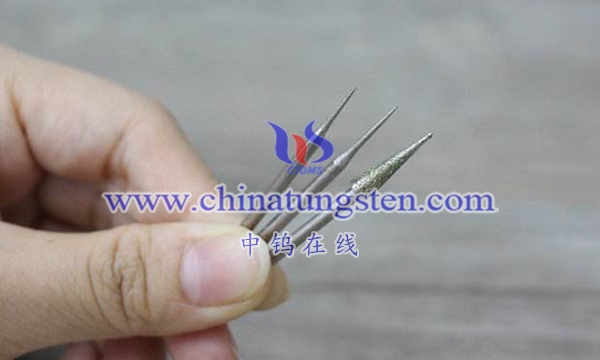

Straightened tungsten wire has the advantages of high purity, high density, high strength, high hardness, high wear resistance and good electrical conductivity, so it is widely used in many fields. In the electronics industry, straightened tungsten wire is used to manufacture heating elements and electrodes in electronic tubes, transistors and other devices. In addition, straightened tungsten wire is also used to manufacture heating elements in high-temperature furnaces, additives in tool steel, etc.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595