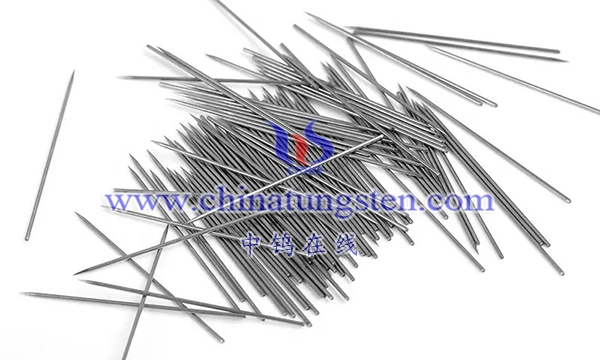

Tungsten wire straightening is an important part of the tungsten wire processing process. Through straightening, the tungsten wire can achieve the required straightness and surface quality to meet the requirements of subsequent applications. The methods and steps of tungsten wire straightening processing will be introduced in detail below.

1. Preparation work

Before performing tungsten wire straightening processing, the following preparations need to be made:

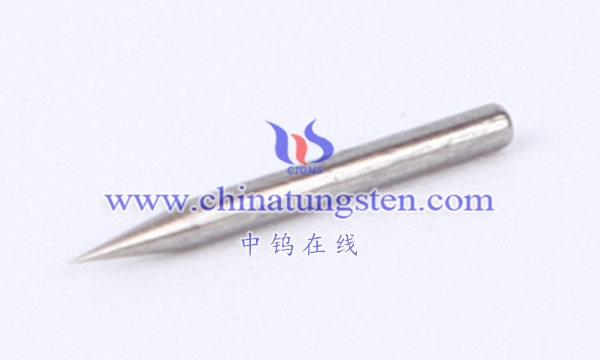

1. Understand the material and characteristics of tungsten wire: As a high melting point metal, tungsten wire has high density, strength and hardness, and also has good electrical conductivity and corrosion resistance. Before straightening processing, it is necessary to understand the material and characteristics of tungsten wire in order to choose the appropriate straightening method and process parameters.

2. Prepare straightening equipment and tools: According to the characteristics of the tungsten wire and the required straightness and surface quality, prepare the corresponding straightening equipment and tools, such as straightening machines, straightening molds, heat treatment equipment, etc.

3. Check the quality and size of the tungsten wire: Check the tungsten wire that is about to be straightened, including appearance quality, dimensional accuracy, etc., to ensure that it meets the requirements for straightening.

2. Straightening treatment

When performing tungsten wire straightening processing, the following steps are generally required:

1. Heat treatment: Before straightening, the tungsten wire needs to be heat treated to eliminate its internal residual stress, increase its strength and hardness, and improve its processing performance. The temperature and time of heat treatment need to be determined according to the material and characteristics of the tungsten wire.

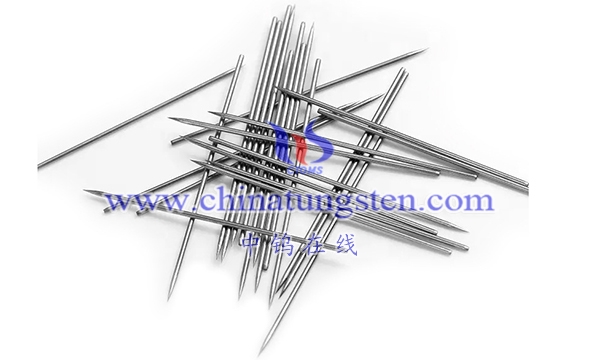

2. Straightening: After heat treatment, put the tungsten wire into the straightening machine for straightening treatment. The straightening machine generally consists of multiple straightening wheels. By adjusting the speed and pressure of the straightening wheels, the tungsten wire can be corrected point by point to achieve the required straightness and surface quality. During the straightening process, attention needs to be paid to controlling the pressure and rotation speed of the straightening wheel to avoid excessive stress on the tungsten wire, which may cause cracks or deformation.

3. Surface treatment: After straightening, the tungsten wire needs to be surface treated to eliminate surface defects and burrs and improve its aesthetics and performance. Surface treatment methods include mechanical polishing, chemical etching, etc.

4. Quality inspection: After completing the above steps, the tungsten wire needs to be inspected for quality, including appearance quality, dimensional accuracy, density and hardness, etc. Quality inspection is an important step to ensure that tungsten wire meets the requirements, so the quality and accuracy requirements of each link need to be strictly controlled.

5. Packaging and storage: Tungsten wire that has passed the quality inspection needs to be packed and stored for subsequent application. When packaging and warehousing, you need to pay attention to clearly labeling the specifications, models, quantities and other information of the product so that you can quickly find the required product during subsequent use.

The following matters need to be paid attention to when performing tungsten wire straightening processing:

1. Operators must undergo professional training and qualification before operating to ensure operational safety and product quality.

2. During the heat treatment process, the heating speed and temperature need to be controlled to avoid defects such as overheating and overburning.

3. During the straightening process, attention should be paid to controlling the pressure and rotation speed of the straightening wheel to avoid excessive stress on the tungsten wire, which may cause cracks or deformation.

4. During the surface treatment process, attention should be paid to controlling the treatment temperature and treatment time to avoid excessive stress on the tungsten wire, which may cause cracks or deformation.

5. During the quality inspection process, the quality and accuracy requirements of each link need to be strictly controlled to ensure that product quality meets the requirements.

6. When packaging and warehousing, you need to pay attention to clearly labeling the specifications, models, quantities and other information of the product so that you can quickly find the required product during subsequent use.

7. Pay attention to production safety issues during the entire processing process, such as wearing protective clothing, regularly checking the safety status of equipment, etc.

In short, tungsten wire straightening processing is an important link in the tungsten wire processing process. By selecting appropriate processing methods and process parameters, high-quality tungsten wire products can be obtained. During the processing process, we need to pay attention to safety issues and control the quality and precision requirements of each link to ensure that product quality meets the requirements.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595