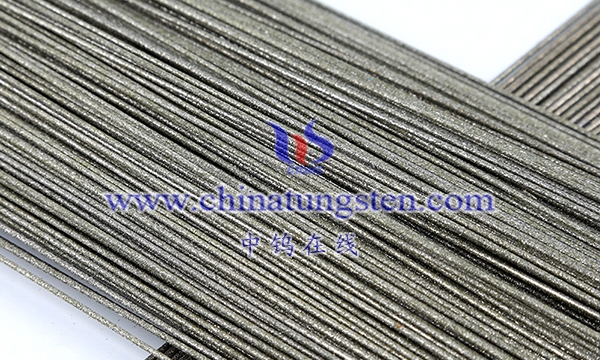

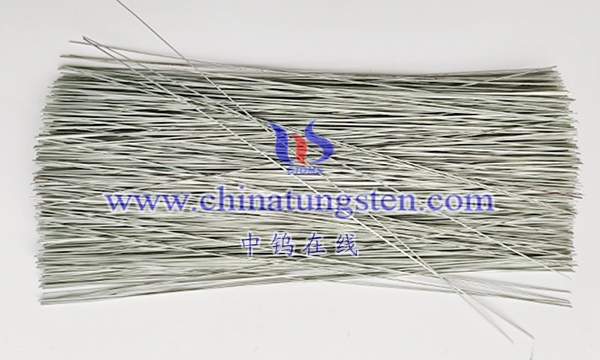

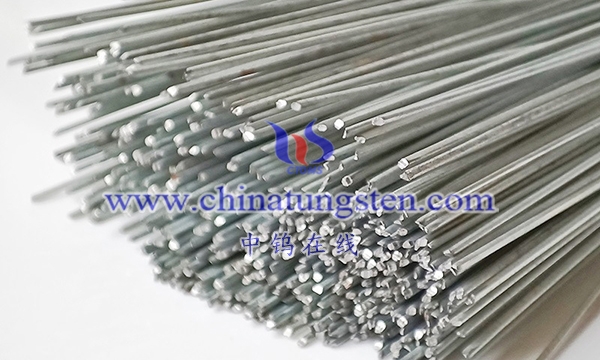

The grinding of the tip of the tungsten needle is a very important link in the production process of the tungsten needle, which directly affects the quality and performance of the tungsten needle. The following will introduce in detail how to polish the tip of the tungsten needle.

- Grinding equipment

The equipment for grinding the tip of tungsten needles mainly includes grinders, polishers and ultrasonic cleaning machines. Among them, the grinder is used for rough grinding and semi-fine grinding, the polishing machine is used for fine polishing, and the ultrasonic cleaning machine is used for cleaning.

- Polishing process

- Rough grinding: Use a grinder for rough grinding to initially smooth the tip of the tungsten needle. During this process, attention needs to be paid to controlling the rotational speed and pressure of the grinding wheel to avoid excessive stress on the tungsten needle, which may cause cracks or deformation. At the same time, water needs to be continuously added for cooling to prevent the tungsten needle from overheating and deforming.

- Semi-fine grinding: On the basis of rough grinding, use a grinding wheel with a lower speed and smaller pressure for semi-fine grinding to grind the tip of the tungsten needle into the required angle and shape. During this process, attention needs to be paid to controlling the rotational speed and pressure of the grinding wheel, as well as the grinding amount, to ensure uniform and smooth grinding.

- Fine polishing: Use a polishing machine and polishing cloth to finely polish the tip of the tungsten needle to remove fine scratches and burrs and improve its surface finish. During this process, attention needs to be paid to controlling the polishing time and polishing pressure, as well as the selection and quality of the polishing cloth.

- Cleaning: Finally, use an ultrasonic cleaning machine to clean the tungsten needle to remove residual grinding and polishing agent and other impurities to ensure the cleanliness and quality of the tungsten needle.

- Precautions

- During the entire grinding process, the equipment needs to be kept clean and hygienic to avoid contamination and foreign matter adhering to the tungsten needle.

- Operators must undergo professional training and qualification before operating to ensure operational safety and product quality.

- During the grinding process, attention needs to be paid to controlling the selection and quality of the grinding wheel, as well as parameters such as grinding time and pressure, to avoid excessive stress on the tungsten needle that may cause cracks or deformation.

- During the cleaning process, attention should be paid to controlling the cleaning time and the selection and quality of cleaning agents to ensure that the cleaning effect meets the requirements.

- During the entire grinding process, attention should be paid to production safety issues, such as wearing protective clothing and regularly checking the safety status of the equipment.

In short, the grinding of the tungsten needle tip is a very critical link in the tungsten needle production process. It directly affects the quality and performance of the tungsten needle. Therefore, when grinding the tungsten needle tip, it is necessary to strictly control the grinding process and parameters and pay attention to safety issues and product quality issues, etc. To ensure the production of high-quality tungsten needle products.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595