The production of high-precision tungsten needles requires strict control of the production process and processing parameters to ensure that the dimensional accuracy, shape accuracy and surface quality of the tungsten needle meet the requirements. The following will introduce in detail how to produce high-precision tungsten needles.

1. Raw material control

The raw materials for producing high-precision tungsten needles must meet the requirements, and tungsten powder or tungsten strips that have been strictly screened and inspected are selected. When purchasing tungsten powder or tungsten rods, it is necessary to conduct a comprehensive test on its purity, granularity, hardness, etc. to ensure the stable and reliable quality of the raw materials.

2. Mold design

The mold is one of the key equipment for producing tungsten needles. The design of the mold directly affects the shape and dimensional accuracy of the tungsten needles. Therefore, when designing the mold, it is necessary to select appropriate materials and processing techniques to ensure the accuracy and service life of the mold. At the same time, regular maintenance and upkeep of the mold is required to ensure its accuracy and reliability.

3. Production process control

The production of high-precision tungsten needles requires the use of advanced production processes and technologies, including heat treatment, straightening, bending, surface treatment, etc. In each production link, processing parameters and technical requirements need to be strictly controlled to ensure that the tungsten needles produced meet the accuracy requirements.

1. Heat treatment: Heat treatment can change the internal structure of the tungsten needle, improve its strength and hardness, and eliminate internal stress. During the heat treatment process, the heating temperature and time need to be controlled to ensure that the heat treatment effect meets the requirements. At the same time, attention needs to be paid to the oxidation and decarburization phenomena produced during the heat treatment process to avoid affecting the surface quality of the tungsten needle.

2. Straightening: Straightening is an important step in the production process of tungsten needles. Straightening can eliminate the bending and unevenness of tungsten needles and improve their straightness and surface quality. During the straightening process, it is necessary to select appropriate straightening methods and tools, and control the straightening pressure and times to ensure that the straightening effect meets the requirements.

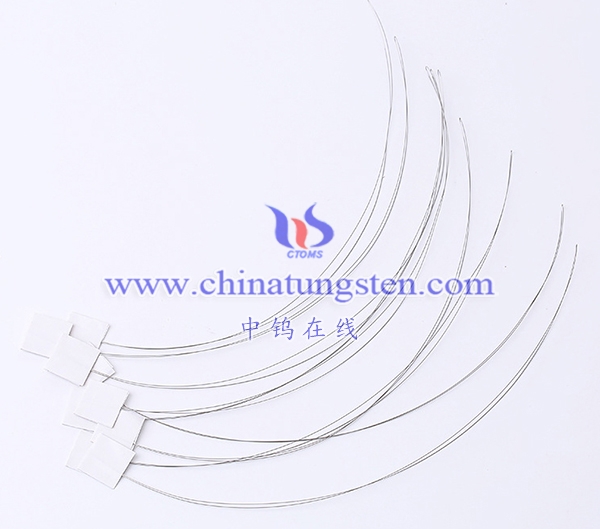

3. Bending and forming: Bending and forming is a key step in the tungsten needle production process. By bending the tungsten needle into the required shape, the required arc and angle can be obtained. During the bending forming process, it is necessary to select appropriate bending methods and tools, and control the bending strength and angle to ensure that the forming effect meets the requirements.

4. Surface treatment: Surface treatment can eliminate defects and burrs on the surface of the tungsten needle, improving its aesthetics and performance. During the surface treatment process, it is necessary to select appropriate treatment methods and process parameters, such as mechanical polishing, chemical corrosion, etc., as well as control the treatment temperature and treatment time to ensure that the treatment effect meets the requirements.

4. Quality inspection

The production of high-precision tungsten needles requires strict quality inspection, including appearance quality, dimensional accuracy, density and hardness, etc. After each production link, corresponding quality inspections need to be carried out to detect and deal with problems in a timely manner to avoid affecting subsequent production. At the same time, random inspection or full inspection needs to be carried out on the final product to ensure that the product quality meets the requirements.

5. Packaging and warehousing

Tungsten needles that pass the quality inspection need to be packaged and stored in storage for subsequent use. When packaging and warehousing, you need to pay attention to clearly labeling the specifications, models, quantities and other information of the product so that you can quickly find the required product during subsequent use. At the same time, attention needs to be paid to keeping the warehouse dry, ventilated and clean to prevent the tungsten needle from being contaminated or damaged.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595