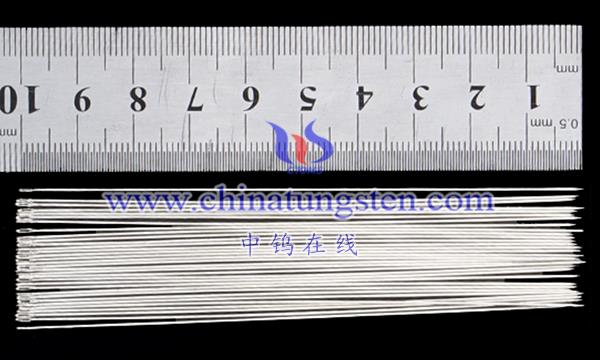

The production and processing of micron-level tungsten needle tips requires the use of a series of advanced processing technologies and processes to ensure that the shape, size and surface quality of the tungsten needle meet the requirements. The following will introduce several commonly used micron-level tungsten needle tip production and processing technologies.

- Mechanical processing technology

Mechanical processing technology is one of the commonly used processing methods for producing micron-sized tungsten needle tips. It includes turning, milling, drilling and other processing methods, and can be used to process tungsten needles of various shapes and structures. In machining, it is necessary to select appropriate tools and cutting parameters, such as cutting speed, feed speed and cutting depth, to obtain the best processing effect. At the same time, attention needs to be paid to monitoring and controlling the processing process to ensure processing quality and accuracy.

- Electrical discharge machining technology

Electrical discharge machining technology is a technology that uses the principle of electric spark corrosion to achieve material processing. In EDM, spark discharge occurs between the tool and the workpiece, causing the workpiece material to be corroded and removed. EDM technology is suitable for processing various hard materials and complex shapes, and can obtain high-precision and high-quality surfaces. When producing micron-sized tungsten needle tips, EDM technology can be used to manufacture tungsten needles with special shapes and structures.

- Laser processing technology

Laser processing technology is a technology that utilizes the high energy and high precision of laser beams to achieve material processing. In laser processing, the laser beam irradiates the surface of the material, generating high temperature and high pressure, causing the material to be melted and removed. Laser processing technology is suitable for precision processing of various materials and can obtain high-precision and high-quality surfaces. When producing micron-sized tungsten needle tips, laser processing technology can be used to create tungsten needles with smooth surfaces and fine structures.

- Nanoimprint technology

Nanoimprint technology is a nanoscale manufacturing technology based on the imprinting principle. In nanoimprinting, a template with nanoscale precision and shape is used to press the imprint glue into the material to be processed, thereby creating nanoscale structures with specific shapes and sizes. Nanoimprint technology can be used to manufacture nanoscale parts and devices of a variety of materials and structures, including tungsten tip tips. By using nanoimprint technology, a tungsten tip with high precision and quality can be obtained.

- Ion beam processing technology

Ion beam processing technology is a technology that utilizes the high energy and high precision of ion beams to achieve material processing. In ion beam processing, a high-energy ion beam generated by an ion source is irradiated onto the material surface, causing atoms on the material surface to be sputtered and removed. Ion beam processing technology is suitable for precision processing of various materials and can obtain high-precision and high-quality surfaces. When producing micron-sized tungsten needle tips, ion beam processing technology can be used to create tungsten needles with smooth surfaces and fine structures.

In short, the production and processing of micron-level tungsten needle tips requires the use of a series of advanced processing technologies and processes. Appropriate processing methods and equipment are selected according to different needs, and processing parameters and quality inspection are strictly controlled to ensure the production of tungsten needles. Meet the requirements. At the same time, attention should be paid to production safety issues, such as wearing protective clothing and regularly checking the safety status of equipment. Only in this way can high-quality micron-level tungsten needle products be produced to meet the needs of different fields.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595