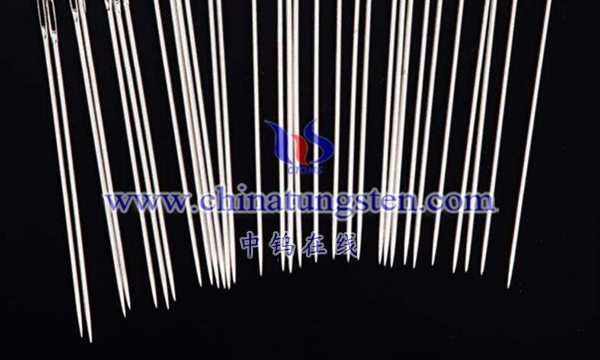

Tungsten needle pins have excellent high temperature performance, making them ideal for many high temperature applications.

First, tungsten needle pins can withstand extremely high temperatures. High temperatures are necessary when welding and cutting metal because it can melt and shear the metal. However, for general metal materials, high temperatures are likely to cause them to deform or melt, while tungsten needle pins can withstand high temperature conditions and maintain their integrity and shape.

Note, however, that the strength of tungsten may decrease at high temperatures. This is because as the temperature increases, the crystal structure changes, causing the plasticity and toughness of tungsten to decrease. In addition, tungsten needle pins are prone to sintering, oxidation and evaporation at high temperatures. Therefore, when using tungsten needle pins for high-temperature processing, it is necessary to select the appropriate tungsten material and reasonable processing technology according to the specific situation to prevent the strength of the tungsten needle pins from being excessively affected.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595