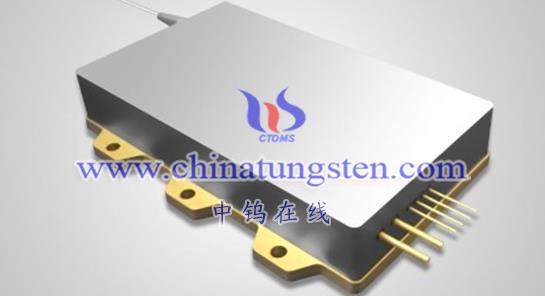

Tungsten alloy industrial electronic packaging chip is an industrial electronic component packaging chip made of tungsten alloy material. Tungsten alloy is an alloy material composed mainly of tungsten element. It has the characteristics of high density, high hardness, high strength and high thermal conductivity. Because tungsten alloy has excellent physical and mechanical properties, it is widely used in various fields, including aerospace, military, petrochemical, nuclear industry, etc.

In the field of industrial electronics, tungsten alloy packaging sheets are widely used in the packaging and heat dissipation of electronic components. Because tungsten alloy has high thermal conductivity, it can quickly conduct heat generated by electronic components and reduce the operating temperature of electronic components, thus improving the stability and reliability of electronic equipment. At the same time, tungsten alloy also has high strength and hardness, and can withstand large mechanical loads and harsh environments, ensuring the stability and reliability of the packaging chip.

The manufacturing process of tungsten alloy industrial electronic packaging chips includes raw material preparation, processing and molding, surface treatment, heat treatment, testing and packaging. First, select the appropriate tungsten or tungsten alloy as the main material, and perform necessary processing and processing, such as cutting, grinding, etc., to obtain the package chip of the required shape and size. Then perform surface treatment, such as grinding, polishing, etc., to improve the surface roughness and cleanliness of the packaging chip, which is beneficial to improving the adhesion and stability of the packaging chip. Heat treatment is then performed to eliminate internal stress and improve mechanical properties and stability. Finally, quality inspection and packaging are performed to ensure the quality and reliability of the packaged chips.

The characteristics of tungsten alloy industrial electronic packaging chips include high strength and reliability, high thermal conductivity, high temperature resistance and corrosion resistance, good electromagnetic shielding performance, and strong customization. These characteristics enable tungsten alloy packaging chips to meet various packaging needs, such as power electronics, automotive electronics, communication electronics, aerospace and other fields.

In the field of power electronics, tungsten alloy packaging sheets can be used to manufacture heat sinks for high-voltage DC power supplies, heat sinks for high-power power supplies, etc. Because tungsten alloy has high thermal conductivity and high strength, it can quickly conduct heat generated by power electronic components and reduce the operating temperature, thus improving the stability and reliability of the equipment. At the same time, the high temperature resistance and corrosion resistance of tungsten alloy also make it an ideal heat dissipation material in power electronic equipment.

In the field of automotive electronics, tungsten alloy packaging sheets can be used to manufacture packaging materials for automotive sensors, actuators and other components. Since the automotive environment is relatively harsh and needs to withstand complex conditions such as high temperature, low temperature, vibration, etc., the requirements for packaging materials are higher. The high strength and stability of tungsten alloy packaging chips enable it to meet the special requirements of automotive electronic components and improve the reliability and life of the equipment.

In the field of communication electronics, tungsten alloy packaging sheets can be used to manufacture heat sinks and shielding materials for communication equipment. Communication equipment needs to transmit large amounts of data at high speeds and is therefore sensitive to electromagnetic interference. Tungsten alloy packaging sheets have good electromagnetic shielding properties, which can effectively reduce the impact of electromagnetic interference and radiation on communication equipment and improve the stability and reliability of the equipment.

In the field of aerospace, tungsten alloy packaging sheets can be used to manufacture heat sinks and thermally conductive structural parts for aerospace equipment. Due to the special requirements of aerospace equipment, they need to withstand extreme temperature and pressure conditions, and materials are required to be lightweight and high-strength. The high strength, high thermal conductivity and high temperature resistance of tungsten alloy packaging sheets make it an ideal heat sink and thermally conductive structural component material in aerospace equipment.

In short, tungsten alloy industrial electronic packaging sheet is a high-performance electronic packaging material with high strength, high thermal conductivity, high temperature resistance and corrosion resistance, and can meet the special requirements for electronic components in the industrial electronics field. Its application scenarios are very wide, including power electronics, automotive electronics, communication electronics, aerospace and other fields. With the continuous development of science and technology, tungsten alloy industrial electronic packaging chips will be used and developed in more fields.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595