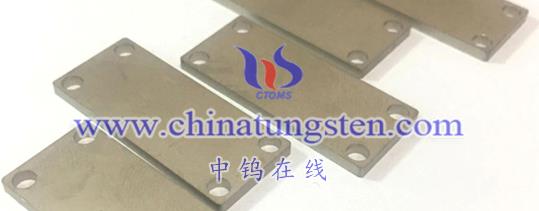

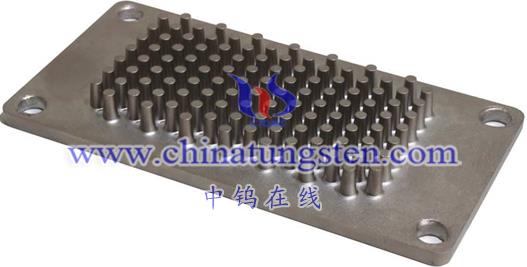

The fusion encapsulation wafer is a kind of encapsulation wafer made by melting process. The melting process is a manufacturing process that manufactures products with required shapes and properties by heating raw materials to a molten state and then performing processes such as injection molding, cooling and crystallization under a certain pressure and temperature. In the manufacturing process of fusion encapsulation chips, materials such as tungsten alloy are heated to a molten state, and then the encapsulation chips are made through processes such as injection molding, cooling and crystallization.

The main advantages and characteristics of fusion encapsulation chips include high strength, high thermal conductivity, high temperature resistance and corrosion resistance. Since the fusion process is able to control the composition and microstructure of the material, it is possible to produce encapsulation chips with excellent properties. For example, tungsten alloy fused packaging sheets have the characteristics of high density, high hardness, high strength and good thermal conductivity, and can meet the requirements of use in harsh environments such as high temperature, high pressure and high load.

The application fields of fusion encapsulated chips are very wide. In the field of electronic packaging, due to its efficient protection of chips and components, it can be used to manufacture various integrated circuit packages, electronic component packages, etc. In the field of automobile manufacturing, it can be used to manufacture high-performance automobile parts due to its high strength and corrosion resistance to key components such as engines, transmissions, and braking systems. In the aerospace field, due to its high requirements on aircraft engines and fuselage structures, it can be used to manufacture high-performance aerospace parts.

In addition, the fusion encapsulation chip also has good customizability. According to the needs of different fields and products, packaging chips of different specifications and shapes can be customized to meet various usage requirements. This kind of customized service can shorten the product development cycle, improve production efficiency, reduce production costs, thereby enhancing the market competitiveness of the product.

To sum up, the fusion method packaging chip is a high-performance packaging material with the advantages of high strength, high thermal conductivity, high temperature resistance and corrosion resistance. Through the melting process, packaging chips with excellent performance can be manufactured to meet the use requirements of different fields and products.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595