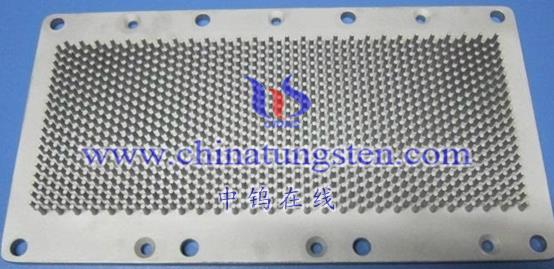

Tungsten alloy 3D printing packaging chip is a tungsten alloy packaging chip made using 3D printing technology. 3D printing is an additive manufacturing technology that builds three-dimensional objects by building up materials layer by layer. In the manufacturing process of tungsten alloy 3D printing packaging sheets, tungsten alloy powder is used as raw material, melted by energy sources such as laser, electron beam or heat melt, and then stacked layer by layer to form the required packaging sheet.

The main advantages and features of tungsten alloy 3D printing encapsulation chips include high precision, strong customizability, and rapid manufacturing. 3D printing technology can achieve high-precision manufacturing and reduce material waste and processing time. At the same time, through design software and prototype manufacturing, the design of packaging chips can be quickly iterated and optimized to meet the usage requirements of different fields and products. In addition, 3D printing technology can also create structures and shapes that are difficult to achieve with traditional processing methods, and improve the performance and functionality of packaging chips.

Tungsten alloy 3D printing packaging chips have a wide range of applications. In the aerospace field, tungsten alloy 3D printing packaging sheets can be used to manufacture high-performance aero-engine and spacecraft components, providing high-strength and high-temperature-resistant packaging. In the field of automobile manufacturing, tungsten alloy 3D printing packaging sheets can be used to manufacture key components such as engines and transmissions, providing high-strength and corrosion-resistant packaging. In the field of electronic packaging, tungsten alloy 3D printing packaging sheets can be used to manufacture integrated circuit packaging and electronic component packaging, providing efficient protection.

It should be noted that there are some technical challenges in the manufacturing process of tungsten alloy 3D printing packaging chips. For example, tungsten alloy has the characteristics of high melting point and low vapor pressure, which can easily cause material clogging or oxidation during the printing process. In addition, tungsten alloy has high mechanical properties and thermal conductivity, which requires the use of high-energy beam or high-temperature printing parameters, which places higher requirements on equipment. Therefore, these technical problems need to be solved when manufacturing tungsten alloy 3D printing packaging chips to ensure that the manufactured packaging chips have excellent performance and reliability.

To sum up, tungsten alloy 3D printing packaging sheet is a high-performance packaging material with the characteristics of high precision, strong customization, and rapid manufacturing. Through 3D printing technology, tungsten alloy packaging chips with excellent performance can be manufactured to meet the requirements of different fields and products.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595