The manufacturing process of gold-plated tungsten wire mainly includes the following steps:

1. Tungsten wire preparation

First, high-purity tungsten wire is prepared, which is usually processed by processes such as swaging and drawing. The purity of tungsten wire must be high to ensure its high strength and good electrical conductivity. The diameter and shape of the tungsten wire must meet the requirements for operation during the subsequent gold plating process.

2. Surface treatment

The tungsten wire is surface treated to remove impurities and oxide layers and improve the adhesion and uniformity of the coating. Surface treatment can use chemical etching, mechanical grinding, electrochemical polishing and other methods. Chemical corrosion can remove the oxide layer and impurities on the surface of the tungsten wire, mechanical grinding can further smooth the surface, and electrochemical polishing can increase the smoothness and corrosion resistance of the surface.

3. Gold plating

Coating a layer of gold on the surface of the tungsten wire is usually done by electroplating or chemical plating. Electroplating uses electric current to reduce gold ions into metallic gold, while electroless plating uses chemical reactions to deposit gold on the surface of tungsten wire. During the gold plating process, parameters such as current, time, and temperature must be controlled to ensure the thickness and uniformity of the gold coating. The thickness of gold coating is usually 1-2 microns.

4. Post-processing

Carry out necessary post-processing, such as cleaning, drying, etc., to remove excess chemical reagents and moisture to ensure the quality and performance of gold-plated tungsten wire. Post-processing can use ultrasonic cleaning, drying and other processes to remove residual chemical reagents and moisture to ensure that the gold-plated tungsten wire is clean and dry.

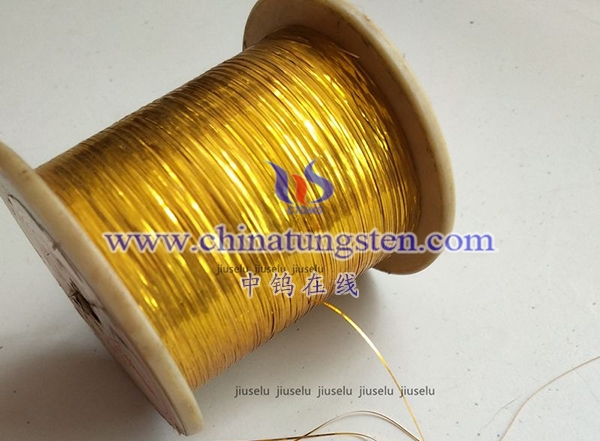

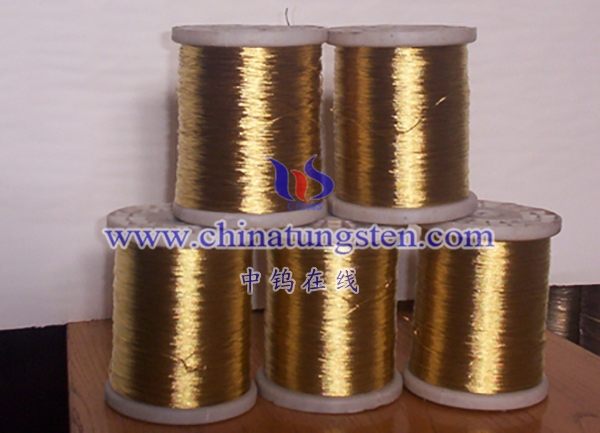

5. Quality inspection and packaging

Conduct quality inspection on gold-plated tungsten wire, including appearance inspection, performance test, etc. Appearance inspection can check the appearance quality of gold-plated tungsten wire, such as whether there are scratches, bubbles and other defects. Performance testing can detect the physical and chemical properties of gold-plated tungsten wire, such as strength, elasticity, corrosion resistance, etc. After passing the quality inspection, the gold-plated tungsten wire is packaged to protect it from damage and contamination. Packaging can be in vacuum packaging or ordinary packaging, depending on product requirements.

The manufacturing process of gold-plated tungsten wire includes steps such as tungsten wire preparation, surface treatment, gold plating, post-processing, quality inspection and packaging. Each step has strict operating requirements and technical standards to ensure the quality and performance of the final product. During the manufacturing process, we must also pay attention to issues such as environmental protection and production safety, and comply with relevant regulations and standards.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595