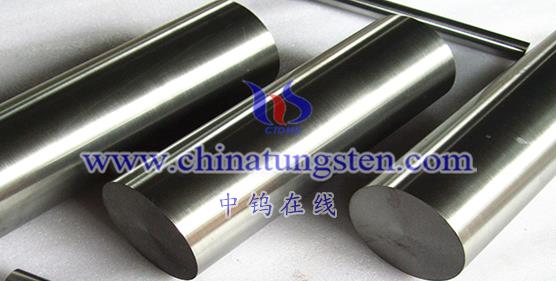

High specific gravity alloy is an alloy material with excellent properties such as high density, high strength, and high thermal stability. It is usually composed of tungsten, cobalt, nickel and other metal elements and is manufactured through specific processing techniques.

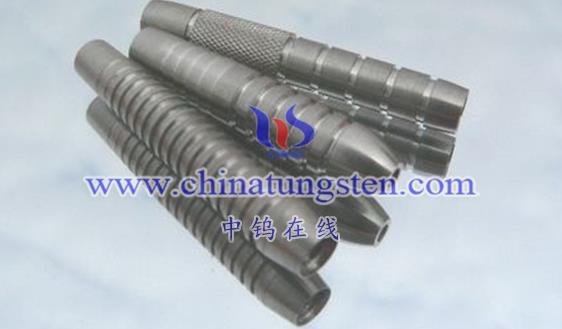

The manufacturing process of high-gravity alloys usually includes steps such as smelting, casting, and heat treatment. During the smelting process, various metal elements need to be melted into a liquid alloy and the ingredients must be evenly distributed. During the casting process, liquid alloy is poured through a specific mold, where it is then cooled and hardened. During heat treatment, the alloy is heated and cooled to adjust its internal structure to obtain the desired physical and mechanical properties.

There are many types of high specific gravity alloys, including tungsten-cobalt alloy, tungsten-nickel alloy, tungsten-ferroalloy, etc. Among them, tungsten-cobalt alloy is a common tungsten alloy, which is composed of tungsten and cobalt and has high hardness, high wear resistance and good corrosion resistance. Therefore, it is widely used in manufacturing various wear-resistant parts and structural parts, such as cutting tools, mining tools, etc.

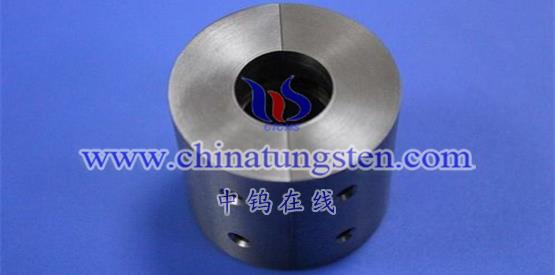

In addition to their applications in manufacturing, high-gravity alloys are also widely used in aerospace, nuclear industry and other fields. For example, in the aerospace field, high-strength, lightweight materials are required to manufacture parts for aircraft and spacecraft. Tungsten-based high specific gravity alloys have excellent properties such as high density, high strength and high hardness, so they are widely used in manufacturing various structural parts and components in aerospace vehicles.

In short, high specific gravity alloy is an alloy material with excellent properties and is widely used in various fields. With the continuous advancement of science and technology and the expansion of application fields, the application prospects of high-gravity alloys will become even broader.

Here are some specific data on high-gravity alloys:

- Density: High-gravity alloys generally have a higher density than pure tungsten, which gives it an advantage in many applications where high density is required. For example, the density of tungsten-cobalt alloy is usually between 15-18 g/cm³, while the density of pure tungsten is about 19.3 g/cm³.

- Hardness: The hardness of high-gravity alloys is usually higher than that of pure tungsten, which gives it better performance in manufacturing wear-resistant parts and structural parts. For example, the hardness of tungsten-cobalt alloy is usually between 80-90 HRC, while the hardness of pure tungsten is about 70 HRC.

- Tensile strength: The tensile strength of high-gravity alloys is generally higher than that of pure tungsten, which allows it to perform better in applications that are subject to greater stress and wear. For example, the tensile strength of tungsten-cobalt alloy is usually between 1000-1500 MPa, while the tensile strength of pure tungsten is about 500 MPa.

- Thermal stability: High specific gravity alloys have good thermal stability and can maintain their physical and mechanical properties in high temperature environments. For example, tungsten-cobalt alloy maintains high hardness and tensile strength at high temperatures, so it is widely used in manufacturing wear-resistant parts and structural parts in high-temperature environments.

- Corrosion resistance: High specific gravity alloys have good corrosion resistance and can resist chemical corrosion and oxidation. For example, tungsten-cobalt alloy maintains high hardness and tensile strength in chemical corrosion and oxidation environments, so it is widely used to manufacture wear-resistant parts and structural parts in corrosion-resistant environments.

In short, high specific gravity alloy is an alloy material with excellent properties and is widely used in various fields. With the continuous advancement of science and technology and the expansion of application fields, the application prospects of high-gravity alloys will become even broader.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595