The main differences between tungsten-cobalt alloy, tungsten-nickel alloy and tungsten-iron alloy are reflected in the composition, physical properties and application fields.

- Ingredients:

- Tungsten-cobalt alloy, also known as tungsten carbide-cobalt hard alloy, can be divided into high cobalt (20% to 30%), medium cobalt (10% to 15%) and low cobalt (3% to 8%) according to the cobalt content. Category three.

- Tungsten-nickel alloy is an alloy with high melting point, high hardness and high corrosion resistance. The nickel content is less than 10% or 10% to 25%, and the balance is tungsten.

- Ferrotungsten alloy is an alloy composed of tungsten and iron, with a tungsten content of 78%-80%.

- Physical properties:

- Tungsten-cobalt alloy has a high elastic modulus and a small thermal expansion coefficient, and is the most widely used type of cemented carbide.

- The specific gravity of tungsten-nickel alloy can be adjusted between 10.0g/cm³-19.3g/cm³. The manufacturing tolerance of parts is small, the density is high, and the relative density is ≥98%.

- The smelting method of ferrotungsten alloy is to heat the furnace charge to a certain temperature range, then add a certain amount of tungsten concentrate and reducing agent mixture. During the feeding period, continue heating to raise the furnace temperature to 2500-3000°C. After adding the materials, continue to add heat to the melt to maintain the slag temperature above its melting point for 7-20 minutes. Stop heating and allow the melt in the furnace to naturally cool to a solid state before being discharged.

- Application areas:

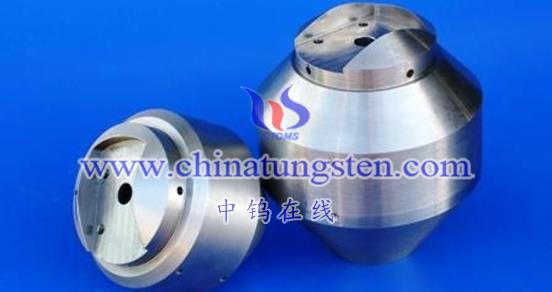

- Tungsten-cobalt alloy is widely used in machinery, electronics, medical equipment, auto parts, aerospace and military industries, daily hardware parts, industrial work molds, etc.

- Tungsten-nickel alloy electroplating process can improve mold quality, extend mold life and clean production. It can also make parts with complex or strange shapes that cannot be made by other molding processes. Suitable for the production of large quantities of parts. Dimensional tolerance ±0.02mm-±0.06mm, single piece weight ±2%-±5%. The specific gravity can be adjusted arbitrarily between 10.0g/cm³-19.3g/cm³.

- Ferrotungsten alloy is often used as an alloy additive in steelmaking.

In general, these three alloys have their own characteristics in terms of composition, physical properties and application fields. For more information, it is recommended to consult a materials engineering expert or consult the relevant literature.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595