High-density tungsten alloy is an alloy material prepared by using tungsten as a matrix and adding other metal elements such as Ni, Fe, etc. through a special processing technology. It has the characteristics of high density, high strength, high hardness and high compactness, and is widely used in aerospace, military, oil drilling and other fields. The preparation process, performance characteristics, application fields and other aspects of high-density tungsten alloy will be introduced in detail below.

- Preparation process of high-density tungsten alloy

The preparation process of high-density tungsten alloy mainly includes powder metallurgy, sintering, extrusion and heat treatment. The purpose of these steps is to ensure the compactness and stability of the alloy’s internal structure.

powder metallurgy

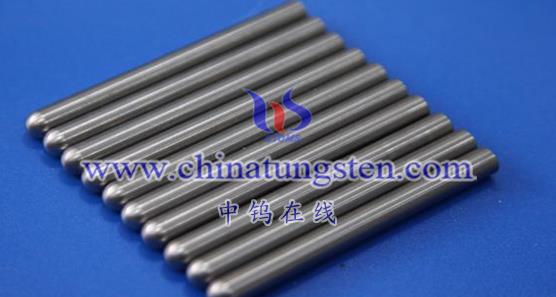

Powder metallurgy is one of the key steps in preparing high-density tungsten alloys. First, the tungsten powder needs to be mixed evenly with other metal elements and pressed into a dense compact. In this step, it is necessary to select the appropriate tungsten powder particle size and pressing pressure to obtain a dense compact.

sintering

Sintering is a key link in the preparation process of tungsten alloy. It is a process in which the atoms and molecules in the tungsten alloy block are diffused and rearranged under a certain temperature and pressure to achieve densification. During the sintering process, temperature and time need to be controlled to avoid defects such as pores and cracks.

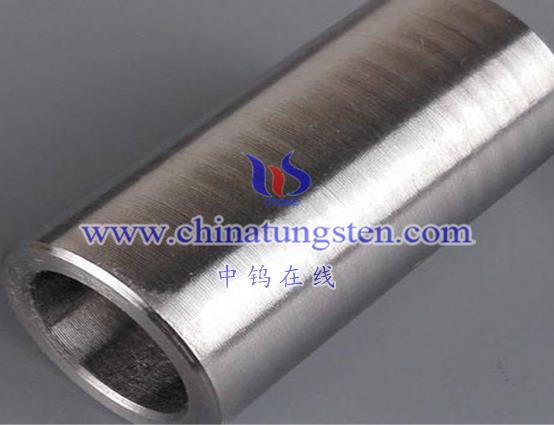

extrusion

Extrusion is the step of extruding the sintered tungsten alloy billet through a die. Through extrusion, the compactness and stability of tungsten alloy can be further enhanced. During the extrusion process, it is necessary to select the appropriate mold and extrusion speed to avoid cracks and deformation.

heat treatment

Heat treatment is an important step in adjusting the internal structure and properties of tungsten alloy. Through proper heating and cooling, internal stress can be eliminated and the strength and hardness of tungsten alloy can be improved. During the heat treatment process, the heating temperature and cooling rate need to be controlled to avoid defects such as cracks and deformation.

- Performance characteristics of high-density tungsten alloy

High-density tungsten alloy has excellent mechanical properties and physical properties. These performance characteristics make it widely used in many fields.

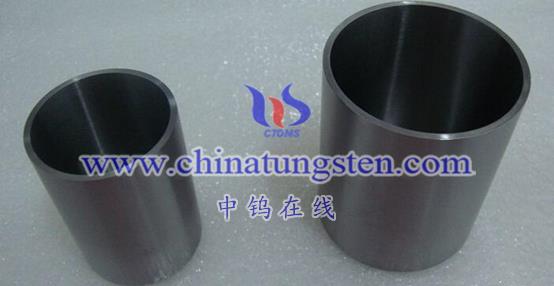

high density

High-density tungsten alloy has a high density, usually above 18.00g/cm³. This high density gives tungsten alloys excellent weight and structural properties in many fields.

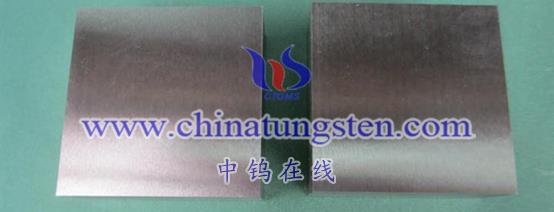

high strength

High-density tungsten alloy has high strength and can withstand large external loads. At normal temperature, the tensile strength and yield strength of tungsten alloy are higher than that of steel. This high strength gives tungsten alloy excellent mechanical properties in situations where it can withstand large loads.

High hardness

High-density tungsten alloy has high hardness and can provide good wear resistance and corrosion resistance. This high hardness gives tungsten alloys excellent properties in terms of wear and corrosion resistance.

High density

High-density tungsten alloy has a highly dense internal structure, which can effectively shield the transmission of electromagnetic waves such as rays and microwaves. This high density makes tungsten alloys have excellent shielding properties in the nuclear industry, aerospace and other fields.

good processing properties

High-density tungsten alloy has good processing properties and can be used for turning, milling, drilling and other mechanical processing operations. This good processing performance makes tungsten alloy have high production efficiency in the manufacturing process.

- Application fields of high-density tungsten alloy

Due to its excellent performance characteristics, high-density tungsten alloy has been widely used in many fields. The following are the main application areas of high-density tungsten alloys:

Aerospace field

High-density tungsten alloy has excellent mechanical and physical properties, making it widely used in the aerospace field. For example, high-density tungsten alloys are used to manufacture parts for spacecraft, rockets and missiles, such as fuel tanks, engine nozzles, missile wings, etc. In addition, high-density tungsten alloys are also used to manufacture components in precision instruments such as aviation instruments and navigation systems.

Military field

The military field is one of the important areas for high-density tungsten alloy applications. Due to its highly dense internal structure and excellent mechanical properties, high-density tungsten alloy is widely used in the manufacture of armor plates for military equipment such as armored vehicles and tanks. In addition, high-density tungsten alloys are also used to manufacture components such as cores and fuze casings in weapons and equipment such as armor-piercing projectiles and armor-piercing projectiles.

Oil drilling field

The oil drilling field is another important area for the application of high-density tungsten alloys. Due to its excellent wear resistance and corrosion resistance, high-density tungsten alloy is widely used in the manufacture of key components such as drill bits and nozzles. In addition, high-density tungsten alloy is also used to manufacture parts of oil production equipment, such as oil pump barrels, plungers, etc.

Other areas

In addition to the above fields, high-density tungsten alloys are also widely used in electronics, medical, nuclear industry, precision machinery and other fields. For example, highly dense tungsten alloys can be used to manufacture precision devices such as electronic components and electrodes, as well as components in medical equipment and the nuclear industry.

- Summary

High-density tungsten alloy is an alloy material that uses tungsten as a matrix, adds other metal elements, and undergoes special processing techniques such as powder metallurgy, sintering, extrusion, and heat treatment. It has the characteristics of high density, high strength, high hardness, high compactness and good processing performance, so it is widely used in aerospace, military, oil drilling and other fields. With the continuous development of science and technology and the increasing demand for applications, the preparation process and application fields of high-density tungsten alloys will continue to expand and innovate.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595