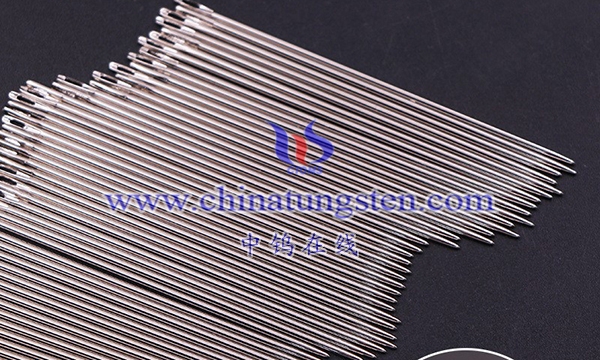

1. Material selection: First, high-quality tungsten steel material needs to be selected to ensure that the probe has high strength and corrosion resistance.

2. Processing and forming: The tungsten steel material is processed into a probe of the required shape, usually by precision turning or milling.

3. Surface treatment: In order to improve the conductivity and corrosion resistance of the probe, the surface of the probe needs to be gold-plated. Gold plating is usually performed by electroplating or chemical plating.

4. Quality inspection: Conduct quality inspection on the gold-plated tungsten steel probe to ensure that it meets the requirements. Common quality inspection items include appearance inspection, dimensional measurement, performance testing, etc.

5. Packaging and shipment: Pack the gold-plated tungsten steel probe well to prevent it from being damaged during transportation. It is usually packed with shock-proof materials to ensure that the product reaches its destination safely during transportation.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595