The main applications of tungsten-molybdenum-nickel-iron alloy in machining include:

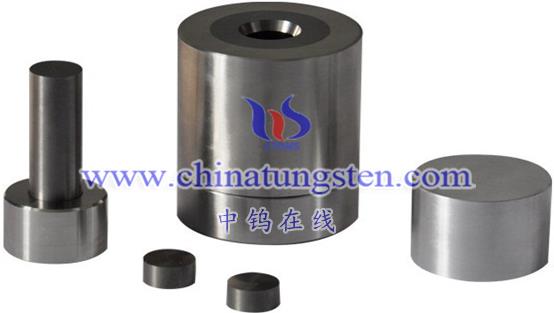

- Die-casting mold field

Tungsten-molybdenum-nickel-iron alloy is widely used in the field of die-casting molds. Due to its low expansion coefficient, high thermal conductivity and good red hardness, this alloy is particularly suitable for die casting processes that need to withstand high temperatures and pressures. During the die-casting process, the mold needs to withstand the high temperature and pressure of the molten metal, so the material is required to have good heat resistance and wear resistance. The high hardness and strength of tungsten-molybdenum-nickel-iron alloy allow it to withstand these extreme conditions, thereby extending the life of the mold.

- Hot riveting bearing materials

Tungsten-molybdenum-nickel-iron alloy can also be used as hot riveting bearing material. This material maintains good mechanical properties and dimensional stability at high temperatures, making it suitable for high-speed, heavy-load working environments. In addition, its good wear resistance can reduce bearing wear and increase bearing service life.

- Hot stamped valves

In the field of hot stamping valves, tungsten-molybdenum-nickel-iron alloy also has a wide range of applications. Because of its high thermal conductivity and high temperature performance, it can still maintain good red hardness at 1100°C, so it is especially suitable for the valve stamping process. The alloy’s high thermal conductivity helps dissipate heat quickly and reduce thermal stress, thereby increasing valve life.

- Cutting tools

The high hardness and wear resistance of tungsten-molybdenum-nickel-iron alloy make it an ideal material for manufacturing cutting tools. This alloy can be used to make various cutting tools such as turning tools, milling cutters, drill bits, etc. During the cutting process, tools need to withstand high temperature, high pressure and severe wear, so the material is required to have good hardness and wear resistance. Tungsten-molybdenum-nickel-iron alloy can meet these requirements and improve the service life and cutting efficiency of cutting tools.

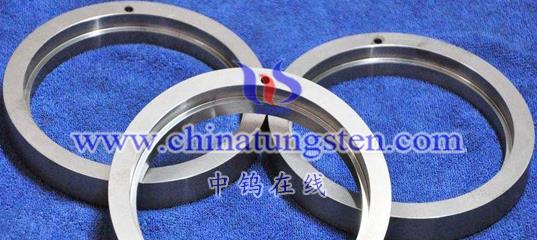

- Other mechanical parts

In addition to the above applications, tungsten-molybdenum-nickel-iron alloy can also be used to manufacture other mechanical parts that need to withstand high temperatures, high pressures and strong corrosion. For example, it can be used to manufacture valves, pump bodies, seals, etc. These components need to withstand extreme temperatures and pressures during operation, so materials are required to have good heat resistance, corrosion resistance and mechanical properties. Tungsten-molybdenum-nickel-iron alloy can meet these requirements and improve the service life and reliability of components.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595