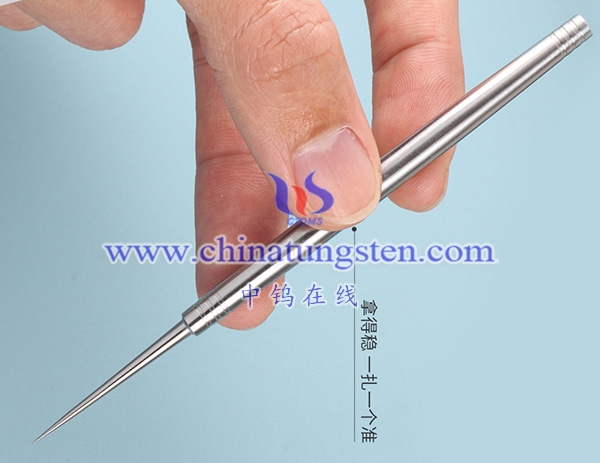

1. High sensitivity: The insulated tungsten-rhenium probe uses advanced electronic technology and digital image processing technology to detect tiny defects on the internal and external surfaces of pipelines and equipment with high sensitivity, and can detect cracks as small as 0.01mm.

2. High resolution: The insulated tungsten-rhenium probe uses high-resolution digital image processing technology to clearly display defects such as cracks, inclusions and corrosion on the internal and external surfaces of pipelines and equipment, providing more accurate detection results.

3. High speed: The insulated tungsten-rhenium probe adopts high-speed detection technology, which can complete the comprehensive detection of the internal and external surfaces of pipelines and equipment in a short time, improving detection efficiency.

4. Wide scope of application: Insulated tungsten-rhenium probes are suitable for testing oil and gas pipelines and equipment made of various materials, such as steel pipes, cast iron pipes, plastic pipes, etc., and have wide applicability.

5. Easy to operate: The insulated tungsten-rhenium probe has a simple structure and is easy to operate. It can be used quickly. It also has the characteristics of automation and intelligence, reducing the burden on the operator.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595